With the rapid development of science and technology and the rapid transformation of the global manufacturing industry, modern manufacturing technology and equipment play a pivotal role in the global context. Mechanical automation technology as an important part of the modern manufacturing field, its advantages in improving production efficiency, cost reduction, product quality and other aspects of the guarantee is becoming more and more prominent, in this context, quality control as a critical link in the manufacturing process, to ensure that the product meets the specifications to meet customer demand and enhance the competitiveness of enterprises has an unignorable role.

1. Difficulties in quality control of mechanical automation technology

1.1 Difficulties in human-machine collaboration

Automation systems usually require operators to work collaboratively with them. If designers ignore human-machine interaction issues, human error risk rises and system safety suffers. For example, CNC machine tool interfaces are usually complex. They contain many parameters and functional options. This complexity can overwhelm users and increase mistakes.

If designers do not reasonably design the operating interface, operators may struggle to understand and use the system correctly. This increases the likelihood of errors, such as miscalculating parameter settings or executing machining instructions incorrectly.

1.2 Data security and privacy are not protected

Machine automation technology involves a large number of sensors and control systems for collecting and transmitting data during the production process, which may contain detailed information on product design, manufacturing and testing, so the generation and transmission of large-scale data increases the risk of data leakage and unauthorized access. Typical manifestations are:

First, connecting automation systems to networks brings cybersecurity risks. Hackers and malware can access system units, steal confidential data, alter production information, or damage automation equipment. These threats harm the accuracy and reliability of quality control.

Secondly, in terms of production privacy, some production environments require the quality control system to include employees’ personal information or production data. However, when companies fail to perfect their automation systems, they struggle to prevent data tampering or leakage during transmission across the supply chain and to ensure proper use of the data at multiple stages. This has become a complex and critical challenge in automated machinery production.

1.3 Problems with data communication and fusion

In the digital manufacturing era, mechanical automation systems generate vast data. Effective communication and integration between devices and systems are essential to support decision-making, quality control, and real-time production optimization.

However, data communication and fusion in mechanical automation face challenges. These include diverse data sources, varying communication standards and formats, as well as real-time and security pressures.

For example, inconsistent data formats and standards are usually one of the difficulties in executing commands in machine automation technology. In an automation system, as the host needs to synchronize the control of devices and sensors from different vendors, which correspond to or use different data formats and communication.

For example, inconsistency in data formats and standards is usually one of the difficulties in executing instructions in machine automation technology. In an automation system, since the host computer needs to synchronize and control devices and sensors from different vendors that correspond to or use different data formats and communication standards, this inconsistency complicates data integration and analysis, making the production process require additional processing steps to solve the data fusion problems, increasing the complexity and development cost of the system.

2. Advantages of the application of machinery automation technology

2.1 Automatic inspection technology improves the quality of automatic production products

In mechanical automation, automatic detection technology plays a key role in improving product quality, reducing costs, and boosting efficiency. It uses sensors, image processing, and data analysis to monitor products in real time during production. This ensures products meet quality standards.

Typical performances include: in the identification of mechanical production modules, using image processing and machine learning technologies, the production equipment can identify and compare the product appearance, size, color, etc. with high precision, which helps to detect surface defects, foreign objects, shape deviation and other issues to ensure that the appearance and size of the product meets the standards.

Optical inspection systems, intelligent sensor networks, and automated defect recognition help achieve full automation of production control. They also enhance product quality throughout the manufacturing process.

2.2 Machine learning to improve production accuracy

The combination of mechanical automation technology and machine learning for the manufacturing industry to bring higher production accuracy, and performance of machine learning algorithms can monitor the production process in real time, according to the results of real-time adjustments and optimization, to ensure that the production parameters are in the best state, and improve the accuracy of production.

For example, an industrial manufacturer uses mechanical automation technology to manage production. The automatic numerical control system can learn automatically. It identifies defective products based on part standards and rejects them directly during production.

From the viewpoint of the machine learning principle of the system, the automatic detection model in the system is based on the RF Random Forest model to identify the parameters of the production parts in the machine production, and the designer will synchronize the design of the regularization parameter S with the number of identifiers of the “tree”, so that the system automatically extracts the number of model groups of the production products, and ultimately estimates the number of model values of each product parameter by using the MCC model algorithm. Finally, the MCC model algorithm is used to estimate the performance corresponding to the model value of each product parameter, and the resulting data can be used to assess the quality level of the production product, as shown in equation (1).

Where, denotes the model parameter values; denotes the number of segments to judge the product signal quality category; denotes the number of segments incorrectly assigned to the product signal quality category.

2.3 Automated production mitigates human factor interference

In modern manufacturing, workers may cause errors due to human factors. In contrast, automated systems perform tasks with a high degree of accuracy and consistency. Mechanical equipment and automation operate continuously without being affected by fatigue, distraction, or other human limitations.

For example, a photocopier production plant in the production of parts, the choice of mechanical automation technology to produce “ef – row fan” parts, in order to avoid the previous production work, usually due to operator fatigue, forgetfulness and other factors leading to the production of mechanical parts failure, the enterprise to implement standardization and Simplification of the production principle, the design and mechanical automation technology as the core of the QC tool, the tool can be in the production line for each component one by one quality comparison, shape comparison, and the existence of production abnormalities in the parts to mark the use of ringing the way to prompt the operator to reassemble, significantly reduce the impact of human factors on the enterprise manufacturing production process.

3. Mechanical automation technology application points

3.1 Coordinate the functional relationship between mechanical structure and automation system.

The main points of the application of mechanical automation technology mainly involves coordinating the functional relationship between the mechanical structure and the automation system to ensure the efficient operation of the system and achieve the expected production goals, such as the technical design of the system integration method, to ensure that the mechanical structure and the automation system between the effective communication protocols, standard interfaces to realize the close interconnection, as well as seamless connection between the different subsystems to achieve the transfer of data and instructions.

So it is crucial to harmonize the functional relationship between the mechanical structure and the automation system.

In this process, the enterprise can take the work approach includes according to the modern manufacturing industry in the operation of mechanical equipment, the use of mechanical automation technology to build the corresponding automation control system, and the control system in the various functional units connected to the mechanical equipment of the various operating port, in order to facilitate the use of automation system functional units to realize the mechanical control.

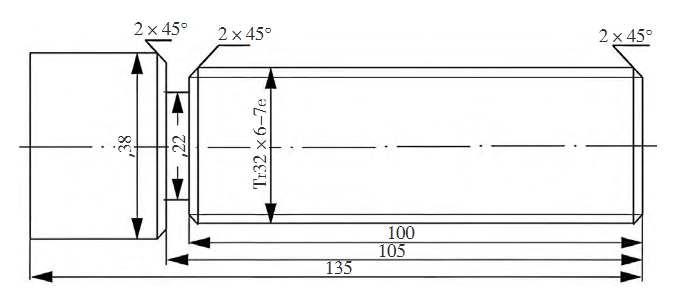

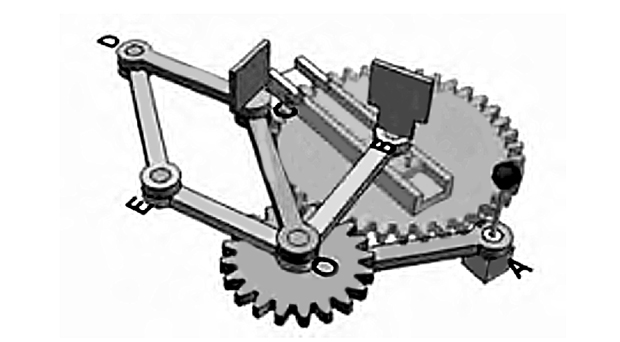

As shown in Figure 1, the figure demonstrates the spectrometer transmission structure in the modern manufacturing industry, under the application of mechanical automation technology, the transmission structure of the A point can be individually controlled using the EWMA control algorithm, by the group operating table to provide operating instructions to the A point of the functional unit to deliver control instructions, so that the structure can be in accordance with the function of the instructions to run in an orderly manner, and make the operation of the B, C, D and other points to be able to Form an R2 type batch control structure framework to improve the application effect of machine automation technology.

Fig. 1 Spectrometer transmission structure

3.2 Optimize the design of mechanical automation controller

Engineers can optimize the design of mechanical automation controllers to improve system stability and control accuracy. By equipping the control system with more precise monitoring and response capabilities, they can reduce system vibration and fluctuations, enhancing consistency and product quality during production.

Under the application of mechanical automation control technology, relevant departments can develop prediction-based control units within the controller design. This allows the control system to timely manage equipment and processing operations according to model instructions.

As shown in equation (2), the control method is based on the RF model to create a model of the control instructions of the automation controller, when the control system recognizes the existence of a new level of factors in the control instructions, the system will be through the training data to form a completely new copy of the modifications, modifications to the copy of the actual variables that can be involved in the production of the product factors and information, and ultimately the inspection of a number of different specifications or design parameters of the manufacturing product Control.

Assuming that the production of a new product involves the production of n parts, the predictive control unit is able to update the training database content, access to multiple parts of the production and design information, and in accordance with the model provides the optimal parameter prediction value to check whether the parts are damaged, the size of the unqualified and so on, so that the modern manufacturing industry, production quality and efficiency has increased dramatically. The prediction-based automation controller design model is shown in equation (2).

Where Uk+1 represents the optimal parameter prediction value calculated under the model; B represents the number of trees; f(x+1) represents the average response value of the terminal node corresponding to the unseen sample; and b represents the number of factors.

3.3 Modeling of algorithmic parameters for optimizing automated control systems

Automation control systems utilize various algorithms to achieve intelligent system control. Different types of systems and application areas may necessitate different control algorithms. PID control algorithms fit many systems, from simple home temperature control to complex industrial processes. MPC algorithms use a system’s dynamic model to predict future behavior. They are suitable for chemical and mechanical systems that require future planning. Algorithm choice depends on the system’s nature, needs, and application. This ensures effective automated control.

And in order to improve the operational efficiency of modern manufacturing and equipment, the relevant departments should properly select the parameters and modeling of the algorithms based on mechanical automation control technology in the following ways:

First, manufacturing often needs multiple machines to work at the same time. Each machine has its own automatic control module for step-by-step processing. The mechanical automation design can use the MPC algorithm. It uses midpoint measurements from different control modules to meet the system’s automation needs in this scenario.

Second, when designing the integrated measurement module, it is important to ensure the mechanical automation system’s control surface covers the entire production area. Therefore, during production, relevant departments should choose a detection algorithm that can assess process qualification. This enables integrated intervention and guides mechanized control operations to minimize process variations, parameter loss, and manual interventions in modern manufacturing.

3.4 Optimize control system design

Optimizing the mechanical automation control system design improves performance, efficiency, safety, and maintainability. Designers model and analyze the entire system in detail. This helps them understand the physical structure, operation principles, and sensor-actuator connections. Such understanding aids in defining the control system’s needs and objectives.

First of all, in the simulation design of the mechanical automation system, one can use differential equations and other mathematical tools as the basis for calculation to describe the dynamics and operation of the system. This allows for the construction of a scientific and reasonable framework for system operation, energy conversion, and physical phenomena.

On this basis, the mechanical automation control system can be designed using a system framework diagram. This diagram shows the relationship between the control system and production equipment. Simulation tests help integrate the two into a unified system. This ensures the equipment operates normally under mechanical automation control.

Secondly, when selecting sensors and actuators, the designer needs to consider the physical quantities obtained from measuring the mechanical control equipment (such as equipment displacement, speed, and shaft transmission structure). Based on these measurements, the designer should choose sensor equipment that meets the application requirements. Additionally, while ensuring the accuracy and resolution of the sensor, the designer should utilize system design algorithms to minimize the sensor’s response time, enabling direct control of machinery through the operating platform. This ensures the feasibility of applying mechanical automation technology.

Conclusion

In conclusion, market competition is intensifying. Consumer demand for better product quality continues to rise. As a result, traditional quality control methods can no longer meet modern manufacturing needs. However, the widespread application of mechanical automation technology offers new possibilities and opportunities for quality control.

In the future, enterprises must focus on problems in quality control during mechanical automation. They should propose improvements and innovations. A comprehensive analysis of challenges and development trends is also essential. This approach will help ensure the sustainable development of modern manufacturing.