Without a doubt, AI is the most popular new technology in recent years. How it provides resistance to traditional manufacturing is a key concern in the industry.

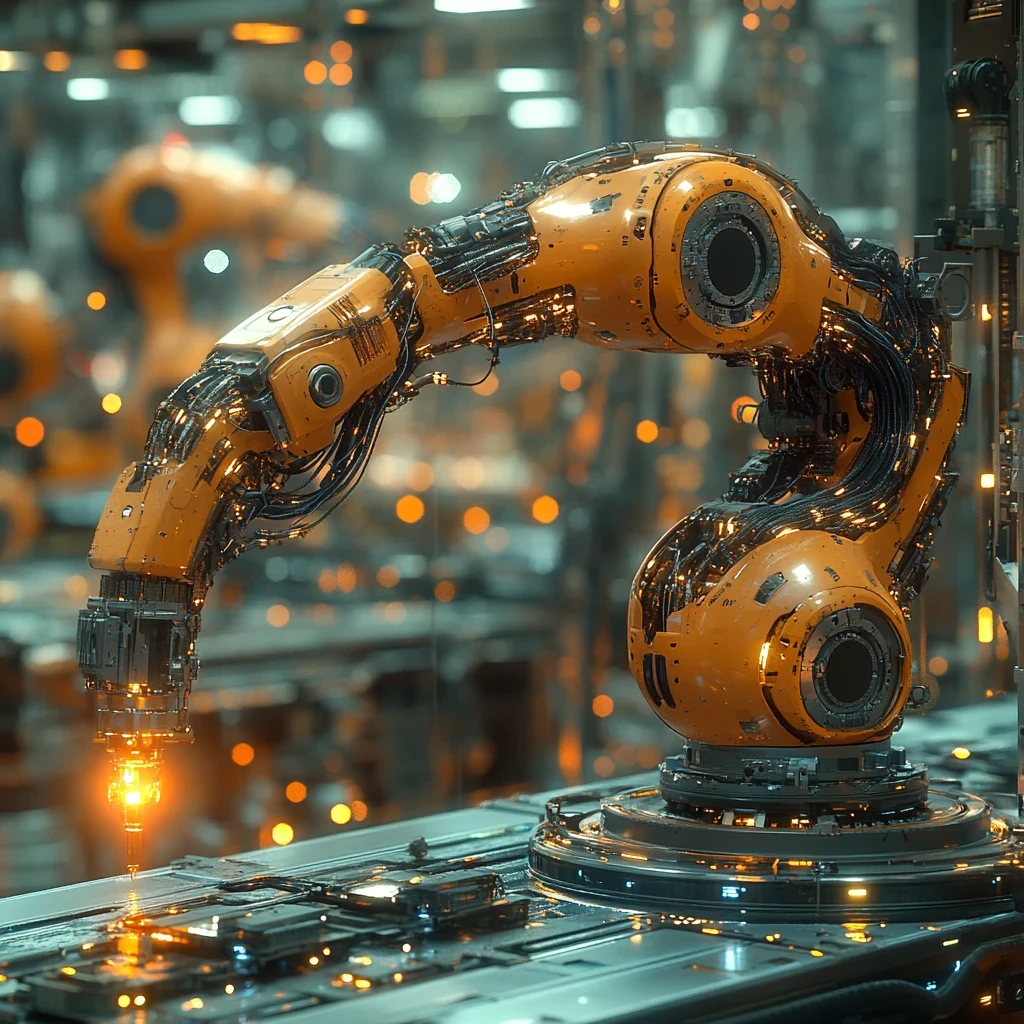

Adjusting industrial production structures, transforming processes, scaling robotic use, building knowledge-intensive organizations, and shifting to efficiency-driven and innovation-driven models align closely with the trend of integrating AI into industrial development. AI vision technology is a key application direction in manufacturing.

What is AI technology?

1. AI Technology Categories

AI technologies applicable to industrial processes include machine learning, NLP, AI vision, deep learning, and human-computer interaction.

Machine learning, as a foundational AI technology, provides supervised or unsupervised process design, training, and classification prediction.

This technology, based on big data, generates responsive solutions to specific problems and includes reward-punishment mechanisms.

Natural language processing focuses on interactions between computers and natural languages, enabling tasks like text analysis, voice recognition, translation, and sentiment analysis.

AI vision refers to using algorithms to mimic human visual capabilities, including image recognition, object detection, reconstruction, and model evaluation.

Deep learning mimics neural networks for personalized and precise recommendations, enabling accurate data analysis and integration of user demands in industrial processes.

It is mainly used in middle and late stages of industrial processes for user demand analysis and precise identification.

Human-computer interaction includes technologies like voice recognition, gesture analysis, and virtual reality, combining NLP, machine learning, and AI vision to enhance interaction experiences.

2. Detailed Explanation of AI Vision Technology

The study and application of AI vision technology can be divided into three stages.

At the early stage, the focus is on collecting features such as surrounding environments, distance, material types, and directions to generate integrated data conclusions.

As the process advances to the mid-stage, coordinate systems are established around the observer, mimicking human recognition to reconstruct and segment objects for comprehensive data collection and analysis.

In the advanced stage, AI vision emulates the functions of human eyes and brains to capture and restore 3D data, drawing on knowledge from computer science, biology, physics, AI, psychology, and economics.

AI Vision Technology in Industrial Manufacturing

1. Main Features

Unlike traditional vision recognition, AI vision in industrial applications meets production needs effectively.

It enables accurate measurement, synchronized coordination, quality inspection, and efficiency improvement.

Beyond traditional use, it spans complex areas like economics, management, sociology, and human interaction.

With diverse subsystems, it ensures efficient, timely operations in complete industrial processes.

For example, AI vision replaces manual inspection in product quality checks, preventing fatigue-related errors.

2. Technical Key Points

2.1 Light Source Technology

Images form the basic recognition objects for AI systems.

Systems convert captured images into analyzable data due to human-computer differences.

Proper light source selection enhances AI vision’s recognition accuracy and system performance.

High-contrast and adaptable lighting solutions have become priorities in AI vision development.

2.2 Signal Processing

Signal processing integrates hardware communication and data interaction.

AI vision relies on advanced circuit integration for complex information processing.

It supports precision machining, intelligent manufacturing, and production line integration.

2.3 Actuators

Actuators are vital to AI vision system applications.

Engineers balance accuracy, stability, feasibility, and energy use.

Modular assembly and process connectivity rely on computing systems for seamless execution.

3. Applications in Industrial Manufacturing

3.1 Automatic Monitoring

AI vision systems adapt to various product inspection requirements.

Automated checks using lasers or CT scans ensure accuracy in models and 3D planning.

3.2 Image Preprocessing

AI systems extract key points and simplify manual image preprocessing tasks.

They provide foundational support for pipeline advancement and module segmentation.

3.3 Template Matching

AI vision measures and matches production processes for accuracy.

It ensures noise resistance, fault tolerance, and controls distortions effectively.

3.4 Template Matching

AI vision optimizes complex assembly processes and minimizes time and labor.

It reduces reliance on specialists by supporting intelligent monitoring and process design.

AI Vision Technology Evaluation and Optimization

1. Advantages of Applications

AI vision improves automation and information processing speeds.

It reduces production errors, handles multi-line tasks, and expands manufacturing possibilities.

For example, it achieves high-precision non-contact measurements, detects weak light, and reduces fatigue.

Initial system setup lowers costs and boosts operational revenue.

2. Application Challenges

2.1 Environmental Demands

AI vision requires stable environments and durable equipment.

High noise or temperature extremes may lower recognition and calculation accuracy.

Extreme conditions may cause equipment failure, affecting industrial processes.

2.2 Privacy Risks

AI in manufacturing raises privacy and data management concerns.

The collection and storage of massive data pose security challenges.

Open-source AI systems may risk privacy while optimizing through large-scale data collection.

3. Optimization Directions for AI Vision Technology in Industrial Manufacturing

3.1 Enhance AI Vision Technology’s Software and Hardware Development

Develop software and hardware to meet AI vision technology’s industrial process needs effectively.

The technology demands high-quality components like lighting, cameras, signal systems, and execution frameworks. Factories must improve command speed and response stability in complex environments to ensure robustness.

3.2 Expand AI Vision Technology’s Application Scope

Tackle sensitivity and interference issues by improving detection, scanning, and planning capabilities in extreme environments.

Introduce low-carbon materials, energy-saving techniques, and human-machine interactive devices to broaden AI vision’s industrial applications.

3.3 Improve AI Vision Technology’s Performance

Prioritize resolution accuracy based on product size and industrial environment needs.

Focus on enhancing image resolution precision for accurate product inspection under various industrial conditions.

3.4 Prioritize Environmental Compatibility Under “Dual Carbon” Goals

Focus on eco-friendly designs by integrating resources like wind and solar energy with stable power supplies.

Plan land use efficiently, develop talent, and ensure sustainable AI vision applications in industry.

3.5 Ensure Safety and Effectiveness of AI Vision Technology

Build firewalls, monitor privacy risks, and establish a security mechanism for compliant data use and safe operation.

Conclusion

AI vision technology revolutionizes traditional manufacturing by solving challenges linked to manual processes.