CNC Machining Services

CNC machining, utilizing automated, high-speed tools, shapes metal or plastic workpieces into desired geometries. Standard machines include 3- to 5-axis milling machines, lathes, and routers, with varying cutting methods.

Our CNC Machining Services

We are constantly prepared to tackle the difficulties posed by stringent tolerances and intricate CNC-machined components. Give our precision CNC machining services a try, and you could be our next delighted customer.

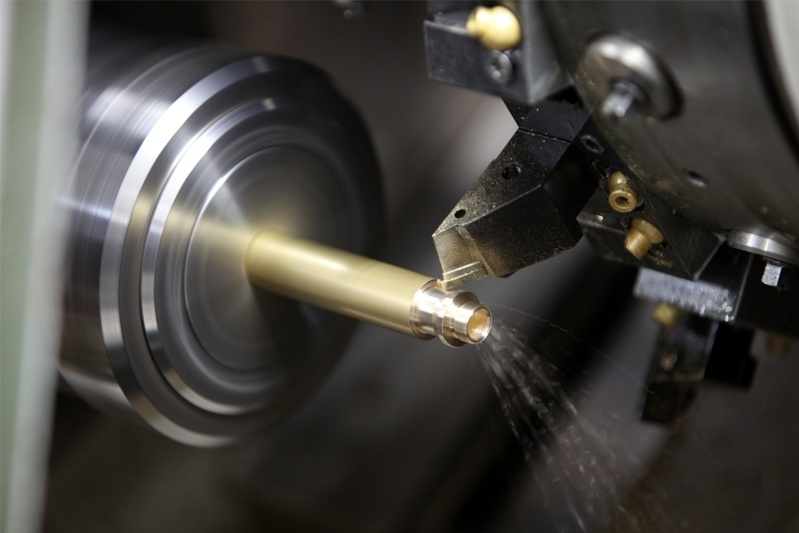

CNC Turning Services

CNC turning represents the optimal method for creating deep holes, threaded surfaces through machining, and various cylindrical forms featuring superior surface finishes. If you require parts that are precisely crafted, quick delivery, and without any restrictions on quantity, Star Rapid’s CNC turning services are the answer. Discover more about how we can assist you.

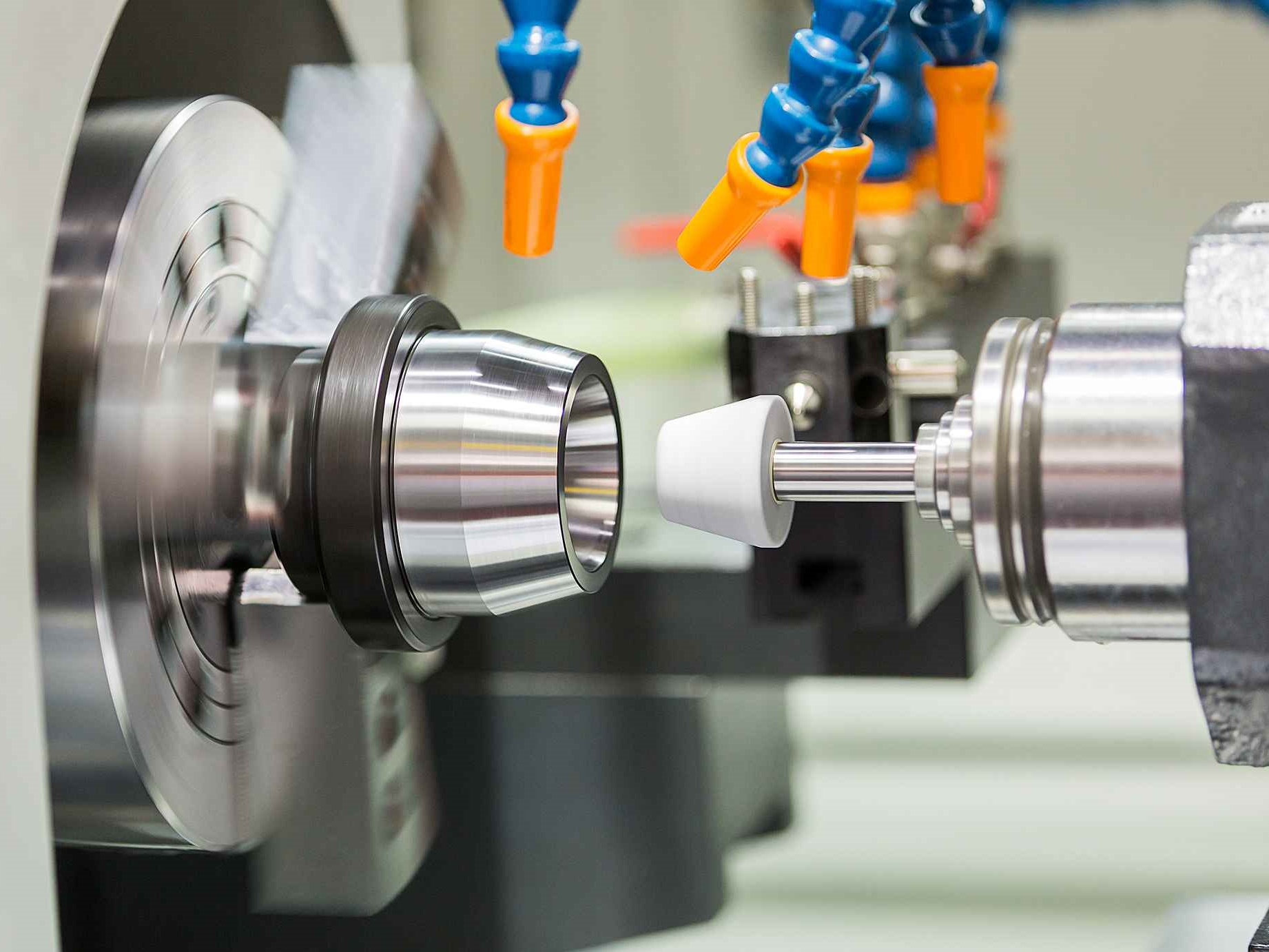

CNC Milling Services

CNC milling enables the creation of intricate prismatic forms and smooth, flat surfaces for a vast array of commercial and industrial applications. Multi-axis metal CNC machines boast unparalleled flexibility, extreme precision, and eliminate the need for static tooling. Discover more about how we can cater to your most demanding CNC milling projects, regardless of quantity.

EMD Services

Electrical discharge machining (EDM) is a specialized type of CNC machining that employs controlled electric pulses to precisely erode even the toughest metals. This technique is crucial when working with hardened tool steels. When executed properly, the resulting surface finish is as smooth as a mirror and necessitates no additional polishing.

CNC Grinding Service

If you require a component with an ultra-flat surface or a round part that necessitates OD and ID tolerances within +/- 0.005mm, our CNC grinding service is ideally suited to meet your production requirements for such parts.

CNC Machining Tolerances

Our metal machined parts have a DIN-2768-1-fine tolerance, while plastic CNC services follow DIN-2768-1-medium. Since part geometry and material can greatly affect tolerances and dimensions, we recommend consulting our engineers beforehand if you have concerns.

CNC Routing Service

In addition to our standard milling services for parts made of engineering plastics or metals, we also provide CNC routing services tailored for prototypes and parts crafted from soft materials, including EPS foam, EVA, and woods.

CNC Machining Materials

From aluminum and steel to brass and plastics, we offer a diverse range of CNC materials for your customized components.

Aluminum, being lightweight, strong, and machinable, is ideally suited for diverse applications such as aerospace and automotive parts. Furthermore, its resistance to corrosion enhances its attractiveness for outdoor projects and structural elements.

Copper, distinguished by its high conductivity and malleability, is a preferred choice for electrical wiring and plumbing. Its natural antibacterial qualities render it suitable for medical uses, while its beauty enhances decorative items and artworks.

Bronze, a copper-tin alloy, is renowned for its durability and corrosion resistance. Its strength and ability to endure harsh conditions make it ideal for marine uses, sculptures, and bearings.

Steel, a robust and versatile material, is widely utilized in construction and manufacturing. Its high tensile strength fits structural components, and subtypes tailor its properties for specialized uses like tools and machinery.

Stainless steel, resistant to rust and staining, excels in kitchen appliances and medical equipment. Its strength and aesthetic charm also render it popular in architectural designs and automotive components.

Magnesium, lightweight yet sturdy, is frequently used in aerospace and automotive fields where weight reduction is vital. Its machinability facilitates complex shapes, and its conductivity makes it valuable in electronic devices.

Titanium, exceptionally strong and lightweight, is perfect for aerospace and medical implants. Its corrosion resistance and biocompatibility boost its use in harsh environments, and its high strength-to-weight ratio fits diverse industrial needs.

ABS is durable, heat- and impact-resistant. Being lightweight and user-friendly, it’s ideal for car components and consumer products where both robustness and cost-effectiveness are crucial.

Polycarbonate is extremely resilient and transparent, featuring outstanding impact strength. Often used in bullet-resistant glass and protective equipment, it can withstand heavy impacts without breaking.

PMMA (acrylic) is transparent, weatherproof, and fade-resistant. Perfect for outdoor exhibitions, signboards, and lighting, it performs well under various environmental conditions.

POM is sturdy and features a low-friction surface, ideal for precision components such as gears and bearings, ensuring a perfect fit and smooth operation where accuracy counts.

Nylon is adaptable, durable, and wear-resistant. It’s frequently selected for gears, bearings, and components enduring constant friction and heat without deterioration.

Lightweight, impact-resistant, and tough, polyethylene is a versatile material suited for packaging, containers, and piping, especially in outdoor and high-moisture conditions due to its chemical resistance and durability.

PEEK is robust and maintains strength at high temperatures. Utilized in high-performance sectors such as aerospace and medical implants, it’s designed for extreme operational environments.

Polypropylene is durable, chemical-resistant, and withstands higher temperatures. It’s widely used in automotive parts, containers, and packaging, particularly where heat or chemical exposure is prevalent.

HDPE boasts exceptional strength and impact resistance, coupled with a high strength-to-density ratio. It’s perfect for bottles, containers, and pipes enduring outdoor conditions.

HIPS is machine-friendly and impact-resistant, making it ideal for prototypes, models, and temporary displays requiring a lightweight yet durable solution.

LDPE is soft, flexible, and crack-resistant, making it suitable for plastic bags, tubing, and shrink wrap applications where heat sealing is a crucial requirement.

PBT is rigid, heat-tolerant, and moisture-resistant. It’s commonly used in electrical parts, automotive components, and industrial connectors in high-heat or damp environments.

PPA provides heat resistance and rigidity, making it perfect for automotive and electrical applications where enduring high temperatures is crucial for longevity.

PAI is renowned for its outstanding thermal and chemical stability, making it a preferred choice for aerospace and automotive industries in high-performance, extreme-condition applications.

PET is sturdy, moisture-proof, and recyclable, making it suitable for food containers, bottles, and textiles, where it maintains durability and resistance to wear and tear over time.

PPS is resistant to heat and chemicals, ideal for automotive, aerospace, and industrial parts exposed to harsh conditions, ensuring they remain solid and stable under stress.

Polystyrene is lightweight and easily moldable, making it a favored choice for models, prototypes, and disposable packaging where shaping flexibility is more important than strength.

PVC is durable, cost-effective, and chemical-resistant, making it suitable for plumbing pipes, medical devices, and electrical cables, where it resists corrosion and withstands wear.

PTFE is resistant to chemicals, has low friction, and remains stable at high temps. It’s often used in non-stick coatings, gaskets, and seals that require robust performance under harsh conditions.

UPE possesses toughness due to its long polymer chains, rendering it suitable for applications requiring abrasion resistance, such as chute linings and heavily used wear-resistant surfaces.

Bakelite is resistant to heat, electrically insulating, and highly durable. It’s used in electrical insulators and vintage electronics where safety and sustained performance are essential.

FR-4 possesses flame retardancy, strength, and electrical insulation properties. It is predominantly utilized in electronic devices for circuit boards and components that must endure high temperatures and electrical pressures.

CNC Machining for Various Industries

Ranging from the automotive sector to aerospace, Ruiyi’s CNC machining caters to the exact requirements of various industries. We collaborate with individual inventors, designers, and large corporations, assisting more than 20,000 clients globally.

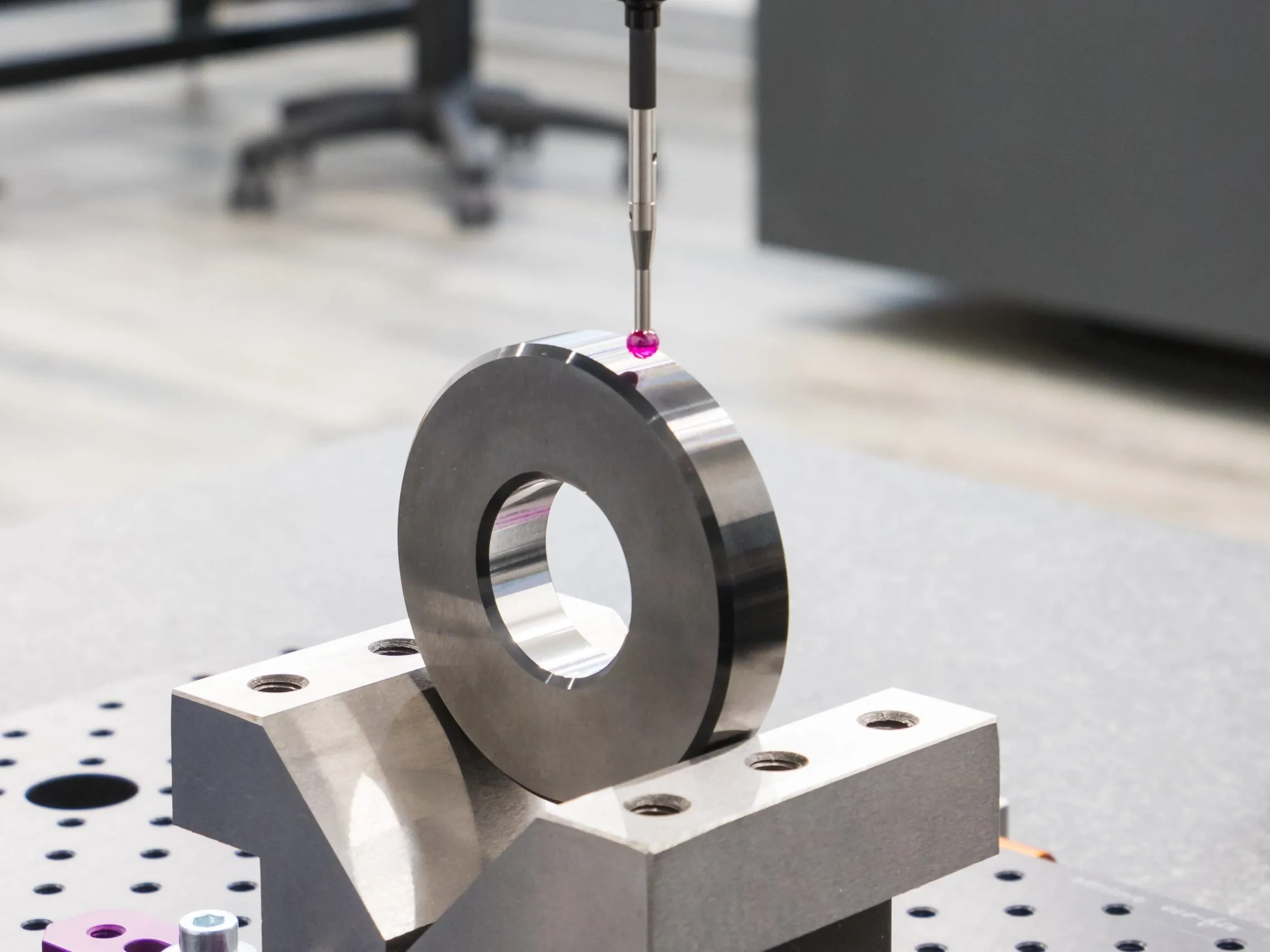

CNC Machining Tolerances

We are able to offer a precision machining service with a wide array of tolerances.

| Feature | Description |

|---|---|

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

| Standard Lead Time | 3 business days |

| General Tolerances | Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

| Precision Tolerances | Xometry can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | Xometry can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Edge Condition | Sharp edges are broken and deburred by default. |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

CNC Machining Solutions

Whether crafting a limited run of bespoke components or ramping up for mass manufacturing, RuiYi’s tailored CNC machining services provide the versatility required.

Rapid Prototyping

Whether you are producing a limited number of customized components or expanding for large-scale manufacturing, RuiYi’s customized CNC machining services provide the adaptability you require.

Low Volume Manufacturing

CNC machining for small batches bridges prototyping to mass production. RuiYi streamlines this, enhancing ease, efficiency, and cost-effectiveness, enabling rapid scaling with top-notch quality.

High Volume Manufacturing

CNC machining excels in producing thousands of parts efficiently. RuiYi uses various materials, automation, and multi-axis capabilities to ensure high-volume production with precision, accuracy, reliability, and swift delivery.

Why Choose Us?

At RuiYi, we believe that CNC machining is more than just a service – it’s a catalyst for innovation. By empowering our clients with fast, affordable, and high-quality prototypes, we help them turn their ideas into reality faster than ever before. Contact us today to learn more about how our cnc machining services can accelerate your product development process and drive your business forward.

Speed & Efficiency

We understand the importance of time in today’s fast-paced business environment. That’s why our cnc machining services are designed to deliver high-quality prototypes within 1-3 business days, ensuring your ideas can be tested and refined with lightning speed.

Advanced Technologies

Employing state-of-the-art 3D printing & CNC machining, we fashion precise, long-lasting prototypes faithful to your design concept. Our expertise spans intricate detailing to intricate geometries, turning your vision into reality.

Cost-Effectiveness

By streamlining the prototyping process and leveraging efficient production methods, we offer cost-effective solutions that fit your budget. This allows you to iterate on your designs without breaking the bank, ultimately leading to a more successful product launch.

Expertise & Support

Our team of experienced engineers and designers are dedicated to providing personalized support throughout your entire prototyping journey. From consultation and design optimization to final prototype delivery, we’re here to guide you every step of the way.

Versatility

Whether you need a single prototype for testing or multiple iterations for refinement, we’ve got you covered. Our cnc machining services cater to a wide range of industries and applications, from consumer electronics and medical devices to automotive parts and aerospace components.