This article introduces the development status of CNC systems worldwide and deeply analyzes the main development trends of CNC technology. The article focuses on the composition of the new generation of intelligent PCNC CNC systems. These systems use a real-time dynamic full-closed-loop control system architecture. This improves system performance and efficiency. The article also explains technological progress in detail. It provides a strong reference for future innovations and applications of CNC systems.

Overview of the development of global CNC systems

With the rapid development of computer technology, traditional manufacturing industries have changed fundamentally. Industrialized countries have made significant investments in researching and developing modern manufacturing technology. They have also proposed a new manufacturing model.

In modern manufacturing systems, CNC technology plays a crucial role. It integrates high-tech fields like microelectronics, computers, information processing, automatic detection, and automatic control. CNC technology is known for its high precision, efficiency, and flexible automation. It is essential for achieving flexible automation, integration, and intelligence in manufacturing.

1. Changes and trends in CNC technology

CNC technology is undergoing significant changes. It is transitioning from a dedicated closed open-loop control mode. Now, it is moving to a general open real-time dynamic full-closed-loop control mode.

With advances in integration, CNC systems are now ultra-thin and ultra-miniaturized. Driven by intelligence, these systems incorporate multidisciplinary technologies, including computers, multimedia, fuzzy control, and neural networks. This enables high-speed, high-precision, and efficient control.

During processing, CNC systems can automatically correct, adjust, and compensate for various parameters. They also offer online diagnosis and intelligent fault-handling functions.

Additionally, with advancements in networking, CAD/CAM systems and CNC systems have achieved deep integration. Machine tool networking and centralized group control processing are now possible, further enhancing efficiency and functionality.

2. Current status of the development of China’s CNC system

For a long time, CNC systems in China have primarily relied on traditional closed-loop architectures. In this setup, CNC functions mainly as non-intelligent motion controllers for machine tools.

Engineers often determine processing variables as fixed parameters based on experience. Operators manually prepare the processing program or generate it using CAD/CAM systems and automatic programming tools. This happens before the actual machining starts.

However, there is no feedback control between the CAD/CAM and CNC systems. As a result, CNC only acts as a closed open-loop actuator in the manufacturing process. This limits its adaptability and intelligence.

3. Limitations of traditional CNC systems

In complex environments with changing conditions, adjusting parameters in real-time is challenging. These parameters include tool combinations, workpiece materials, spindle speed, feed rate, tool trajectory, cutting depth, step length, and machining allowance. External interference and random factors further complicate the process.

Additionally, the lack of feedback control prevents the random modification of set values in CAD/CAM during the processing stage. This limitation negatively impacts the work efficiency and product quality of CNC machining.

4. Necessity of change

The fixed program control mode of traditional CNC systems limits their ability to advance. Their closed architecture also restricts progress toward multivariable intelligent control.

These limitations prevent CNC systems from meeting the increasingly complex manufacturing needs. Therefore, the transformation of CNC technology has become essential.

Development trend of CNC technology

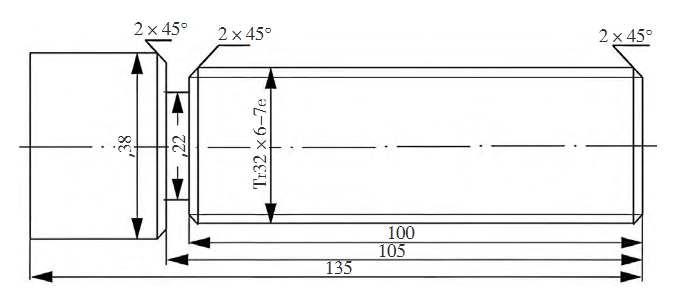

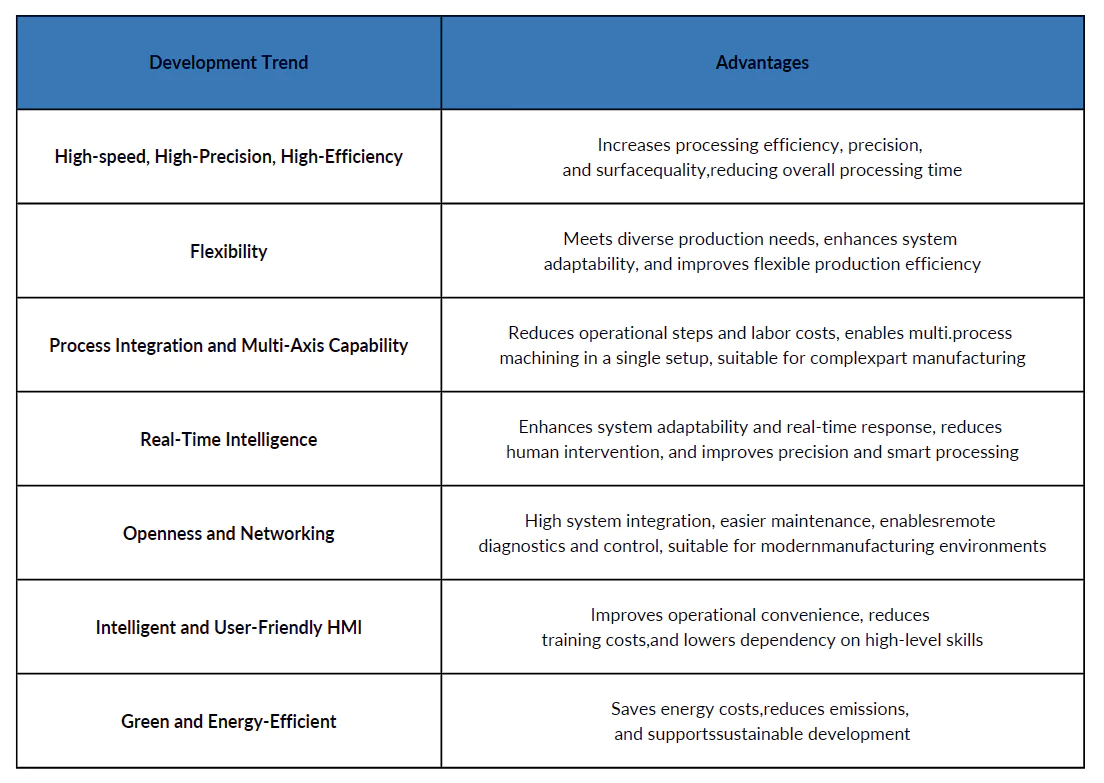

1. Performance development direction

(1) High speed, high precision, and high efficiency

Speed, precision, and efficiency are the key performance indicators of mechanical manufacturing technology. High-speed CPU chips, RISC chips, multi-CPU control systems, and AC digital servo systems with high-resolution absolute detection elements have contributed to these improvements. Additionally, measures to improve the dynamic and static characteristics of machine tools have led to gains. These improvements have increased the speed, precision, and efficiency of machine tools.

(2) Flexibility

It includes two aspects: the flexibility of the CNC system itself. The CNC system adopts a modular design. It has a wide range of functions and is highly customizable. This makes it convenient to meet the needs of different users. The group control system is flexible. It can automatically adjust the material flow and information flow based on the requirements of different production processes. This maximizes the effectiveness of the system.

(3) Process complexity and multi-axis

The main purpose of compound processing is to reduce process and auxiliary time. It is developing towards multi-axis and multi-series control functions. The complexity of CNC machine tools allows them to complete multi-process and multi-surface compound processing.

After clamping the workpiece on a machine tool, various measures can be used. These include automatic tool change, rotating spindle heads, and turntables. The progress of CNC technology has enabled multi-axis control. It also allows multi-axis linkage control. For example, the FANUC15 system can control 2 to 15 axes. The Siemens 880 system can control up to 24 axes.

(4) Real-time intelligence

Real-time intelligent control combines real-time systems with artificial intelligence technology. This enables CNC systems to respond quickly. It also allows them to make intelligent decisions in complex environments. The control method includes various technical applications, such as adaptive control, fuzzy control, and neural network control.

For example, the CNC system can automatically manage and compensate the tool. This is done through programming expert systems and fault diagnosis systems. These systems improve motion control performance during high-speed machining. Additionally, feedforward control and fuzzy control technology allow the CNC system to control pressure, temperature, position, and speed. This ensures the best control effect.

(5) Open and networked

The openness and networking of CNC systems are important directions for future development. Introducing an open system structure allows CNC systems to integrate external devices and functions. This forms a unified platform.

Networking enables CNC equipment to communicate with other devices in real time through the industrial Internet. It supports functions like remote monitoring, fault diagnosis, and parameter optimization. This improves the collaboration and production efficiency of the production line.

(6) Intelligent and friendly human-machine interface

As technology develops, the human-machine interface (HMI) of CNC systems becomes more intelligent and user-friendly. Modern CNC machine tools now have high-resolution touch screens. Operators can control the machines more intuitively. They can also program the machines conveniently. This is possible with technologies like voice recognition and graphical programming. This reduces reliance on the operator’s technical level and improves the convenience and efficiency of operations.

(7) Greening and energy conservation and environmental protection

In the development of CNC technology, green manufacturing, energy conservation, and environmental protection have become important trends. CNC machine tools can reduce energy waste and minimize the environmental impact of the manufacturing process by optimizing energy consumption management and resource utilization.

The CNC system monitors energy consumption in real time and adjusts processing parameters to save energy. Additionally, the use of composite processing technology and efficient cutting tools helps reduce material waste.

2. Functional development direction

(1) Graphical user interface

The user interface serves as the dialogue interface between the CNC system and the user. Different users have different requirements for the interface, which makes developing the user interface a huge task. As a result, it has become one of the most difficult parts of computer software development. Current technologies such as the INTERNET, virtual reality, scientific computing visualization, and multimedia have raised the bar for user interface development.

The graphical user interface makes it much easier for non-professional users to operate. Users can interact through windows and menus, which simplifies blueprint programming and fast programming. It also supports three-dimensional color stereo dynamic graphics display, graphic simulation, dynamic tracking, simulation, different directional views, and local display scaling functions.

(2) Scientific computing visualization

Scientific computing visualization efficiently processes and interprets data. As a result, information exchange is no longer limited to text and language. It can now directly use visual information such as graphics, images, and animations. The combination of visualization technology and virtual environment technology has expanded its application.

Drawing-free design and virtual prototype technology shorten the product design cycle. They also improve product quality and reduce product costs. In numerical control technology, visualization technology is used in CAD/CAM. It supports automatic programming design and automatic parameter setting. It also displays tool compensation, manages tool data, and simulates the processing process visually.

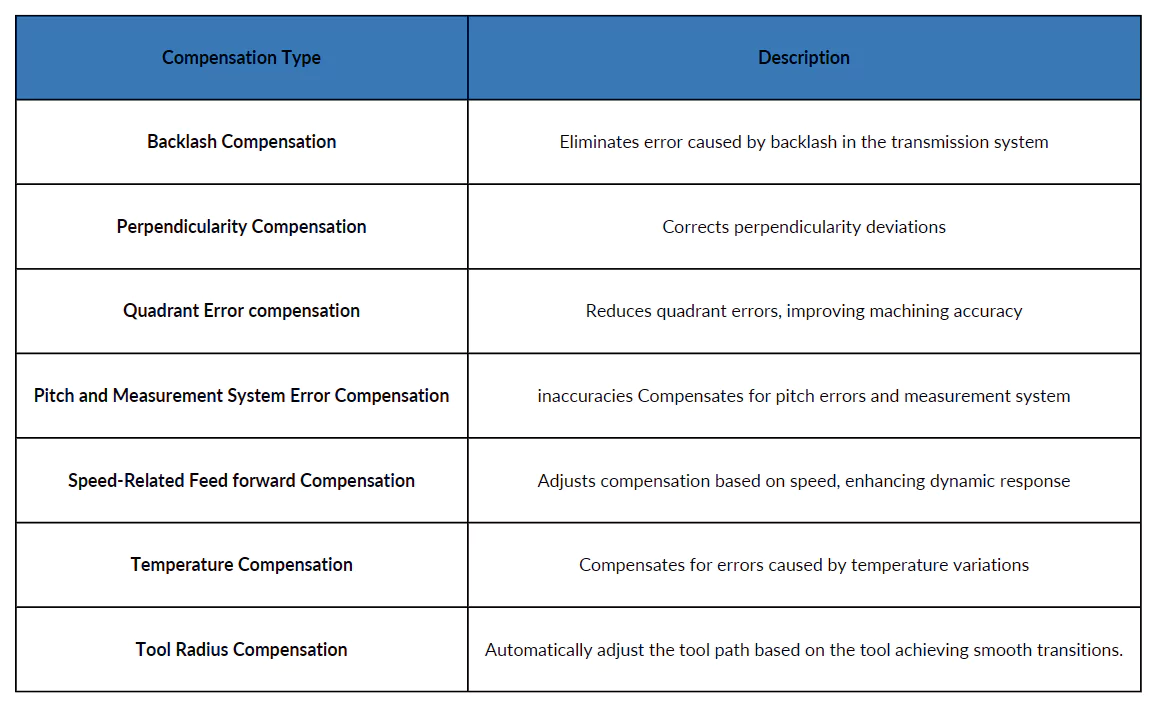

(3) Diversified interpolation and compensation methods

CNC systems use various interpolation methods. These methods include linear interpolation, circular interpolation, and cylindrical interpolation. Other types are spatial elliptical surface interpolation, thread interpolation, and polar coordinate interpolation. There are also 2D + 2 spiral interpolation, NANO interpolation, and NURBS interpolation. Additionally, spline interpolation (A, B, C spline) and polynomial interpolation are used.

Various compensation functions are applied in CNC systems. These include gap compensation, verticality compensation, and quadrant error compensation. There is also compensation for pitch and measurement system errors. Speed-related feedforward compensation, temperature compensation, and tool radius compensation are also implemented. These functions involve a smooth approach and exit, as well as opposite point calculation.

(4) Built-in high-performance

PLC The numerical control system is equipped with a high-performance PLC control module, which can be directly programmed in ladder diagrams or high-level languages, and has intuitive online debugging and online help functions. The programming tool contains standard PLC user program examples for lathes and milling machines. Users can edit and modify the standard PLC user program to easily build their applications.

(5) Application of multimedia technology

Multimedia technology integrates computer, audio-visual, and communication technologies, enabling computers to comprehensively process sound, text, image, and video information. In the field of numerical control technology, the application of multimedia technology can achieve integrated and intelligent information processing and has great application value in real-time monitoring systems fault diagnosis of production site equipment, production process parameter monitoring, etc.

3. Development of architecture

(1) Integration

Using highly integrated CPUs, RISC chips, and large-scale programmable integrated circuits like FPGA, EPLD, CPLD, and ASIC chips can improve the integration of numerical control systems. It also boosts the speed of software and hardware operation. The application of FPD flat panel display technology enhances display performance. Flat panel displays are lightweight, small in size, and have low power consumption. They are easy to carry and can achieve ultra-large-size displays. This makes them a competitive emerging technology, replacing CRTs. They are now the mainstream display technology of the 21st century.

Advanced packaging and interconnection technology integrates semiconductor and surface mounting technologies. By increasing integrated circuit density and reducing interconnection length and quantity, product prices decrease. Performance improves, component size reduces, and system reliability increases.

(2) Modularity

Hardware modularization facilitates the integration and standardization of CNC systems. According to different functional requirements, basic modules such as CPU, memory, position servo, PLC, input and output interface, communication,n, on, and other modules are made into standard series products, and the functions are cut and the number of modules is increased or decreased through the building block method to form CNC systems of different grades.

(3) Networking

Machine tool networking can be remotely controlled and operated unmanned. Through machine tool networking, other machine tools can be programmed, set, operated, and run on any machine tool, and the screens of different machine tools can be displayed on the screen of each machine tool at the same time.

(4) General open closed-loop control mode

General computers are used to form a bus-based, modular, open, and embedded architecture. This makes it easy to cut, expand, and upgrade. It can also form CNC systems of different grades, types, and integration levels. The traditional CNC system uses a closed-loop control mode. This is the only dedicated single-machine closed open-loop control mode.

The manufacturing process is complex, involving multivariable control and processing technology. It includes various factors such as processing size, shape, vibration, noise, temperature, and thermal deformation. To optimize the process, multivariable closed-loop control is needed. This allows dynamic adjustment of process variables during real-time processing.

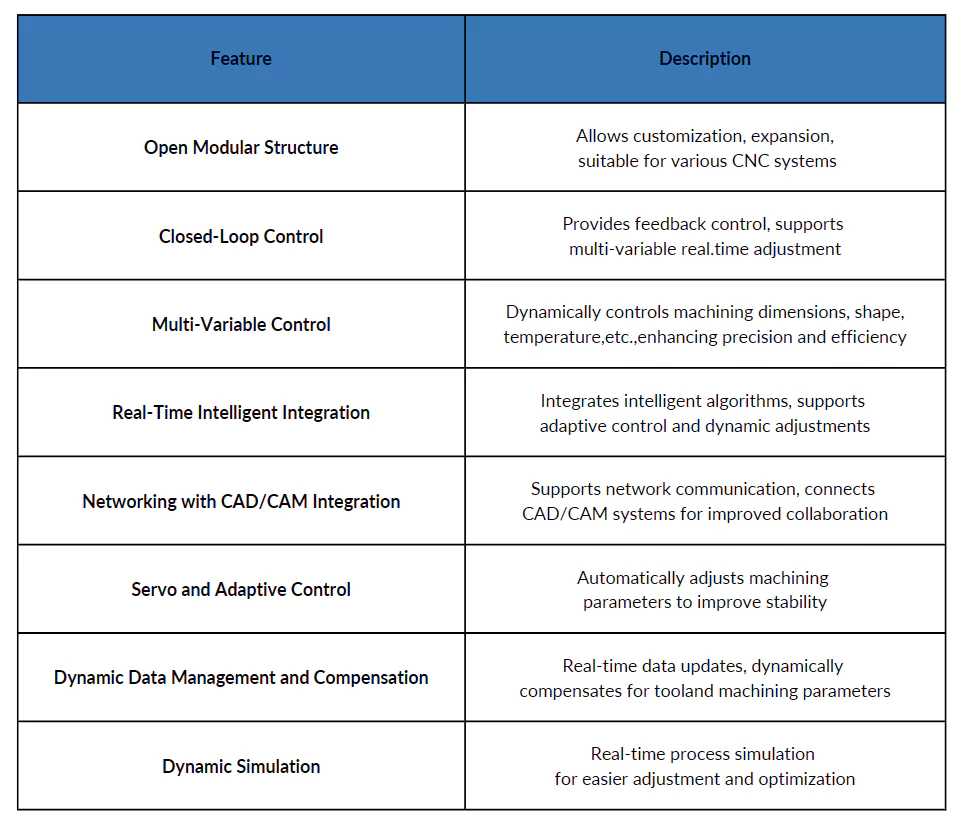

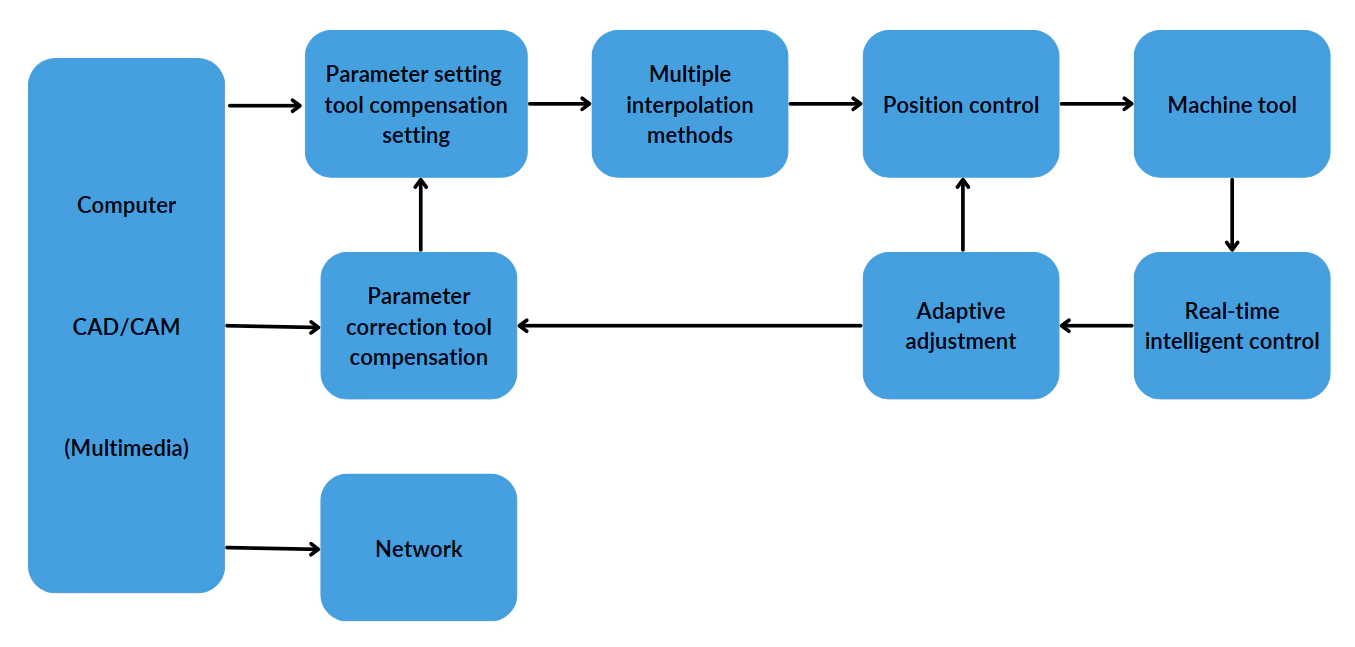

The processing process adopts an open, general real-time dynamic full closed-loop control mode. This mode easily integrates computer real-time intelligent technology, network technology, multimedia, CAD/CAM, servo control, adaptive control, dynamic data management, dynamic tool compensation, and dynamic simulation. These technologies form a strict closed-loop control system, enabling integration, intelligence, and networking.

Intelligent new generation PCNC numerical control system

It is now possible to develop a new generation of intelligent PCNC numerical control systems. These systems use a closed-loop control architecture. This architecture is suitable for complex manufacturing processes. The figure below shows the CNC system’s architecture.

The figure demonstrates how the intelligent PCNC CNC system integrates several advanced technologies. These include computer intelligence, network technology, CAD/CAM, servo control, adaptive control, dynamic data management, dynamic tool compensation, and dynamic simulation. Together, these technologies form a strict closed-loop control system for the manufacturing process.

Conclusion

In summary, CNC system technology is continuously progressing worldwide. This progress is promoting the intelligent and efficient development of the manufacturing industry. The new generation of intelligent PCNC CNC systems has introduced a real-time dynamic full closed-loop control system. This system provides more accurate and flexible control. It lays a technical foundation for future intelligent manufacturing. As CNC systems evolve, they will offer higher performance, greater openness, and more intelligence. This will create broader innovation opportunities and development in the manufacturing industry.