Rapid Prototyping

Rapid prototyping swiftly transforms preliminary design concepts into tangible prototypes, providing an efficient and economical means of visualizing ideas in the physical world. This methodology proves particularly advantageous when leveraging technologies like 3D printing, CNC milling, and others, enabling the production of prototypes generally within 1 to 3 working days.

Our Rapid Prototyping Services

At RuiYi, we specialize in offering state-of-the-art rapid prototyping services that bridge the gap between innovative ideas and tangible realities. Our cutting-edge solutions empower designers, engineers, and entrepreneurs alike to swiftly transform their early-stage concepts into fully functional prototypes, accelerating the product development process and minimizing the time-to-market.

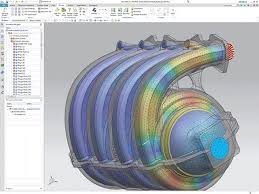

Rapid CNC Prototyping

Service

CNC machining, milling & turning, excels for rapid prototyping of final-material parts. RapidDirect crafts dense, accurate, durable prototypes from various metals & plastics, ensuring versatility. Quick turnaround (1-day) & cost-effective pricing enable bulk orders for swift product evaluations.

Maximum Part Size:

CNC Milling: 4000×1500×600 mm

CNC Turning: 200×500 mm

Standard Lead time: 1 day

Tolerance: 0.001 inches

Rapid PrototypeI Injection Moiding Service

DescriptiInjection molding excels for prototyping durable, uniform parts for rigorous testing. Ideal for high-accuracy product assessments & bridging tools during launches. RapidDirect offers even faster services, delivering parts in just 5 days, compared to usual 2-3 weeks.

Maximum Part Size: 1200×1000×500 mm

Standard Lead time: 2-3 weeks

Mold Cavity Tolerance: +/- 0.05 mm

Rapid Sheet Metal Prototyping Service

Sheet metal fabrication expedites flat part prototyping in final metal form, achieving it in a week or less. Cost-effective & swift, it facilitates parallel development of multiple prototypes. Materials range from Aluminum 5052 to various alloys like steels, copper, & stainless steel.

Cutting Feature: ± .00787” (0.2mm)

Bend Angle: ± 1.0°

Bend to edge: +/-0.010″(0.254mm)

Bend to hole: +/- 0.2 mm

Standard Lead time: 1-2 business days

General Tolerances: Metals : ISO 2768-c

Rapid 3D Prototyping

Service

3D printing stands out in rapid prototyping with its swiftness & cost-effectiveness, enabling same-day prototype delivery. Core techniques: SLS (adaptable, speedy, economical), SLA (superior surface quality, precision), FDM (massive builds, varied materials).

Max. Build Size: 1400x700x500mm

Standard Lead time: 4-6 days

Dimension Tolerance: ±0.2mm (For >100mm, apply 0.15%)

Rapid Vacuum Casting Prototyping Service

Vacuum casting excels in rapid, cost-effective prototyping of high-quality replicas. Ideal for small-medium batches of functional plastics, mimicking injection-molded quality. Precise replication of details & textures for test marketing, functional evaluations, & proof-of-concept.

Maximum Part Size: +/- 0.025 m

Standard Lead time: Up to 20 parts in 15 days or less

Tolerance: ±0.05 mm

JE Machining’s Capabilities On Rapid Prototyping

At RuiYi, we specialize in offering state-of-the-art rapid prototyping services that bridge the gap between innovative ideas and tangible realities. Our cutting-edge solutions empower designers, engineers, and entrepreneurs alike to swiftly transform their early-stage concepts into fully functional prototypes, accelerating the product development process and minimizing the time-to-market.

Multi-material customization available

Using premium materials & rigorous control, we offer diverse resin consumables: opaque, transparent, heat-resistant, & high-strength, catering to diverse industry needs for material properties.

Post Processing

Firstmold’s rapid prototypes undergo multiple polishing stages & one-piece profile cutting to suit your needs. Complex surfaces & functional structures are swiftly crafted with unparalleled precision.

Resource allocation advantages

We offer diverse processing techniques & strict confidentiality, ensuring tight tolerances (±0.02mm). Finished products boast flat, smooth surfaces, attention to detail, & robust prototypes that resist damage.

How to Choose The Right Rapid Prototyping Technique

| Advantages | Disadvantages | |

|---|---|---|

| Rapid CNC Machining | High precision and suitability for a variety of materials. Ideal for functional and durable parts. | Higher cost and longer lead times compared to some additive manufacturing processes. |

| Rapid Injection Molding | Excellent for high-volume production. Provides end-use, functional parts with fine details. | Upfront costs for molds are high, less economical for small quantities. |

| Rapid Sheet Metal Fabrcation | Good for durable prototypes, allows quick modifications. Suitable for both prototyping and production. | Limited complexity, not ideal for intricate designs requiring high detail. |

| Rapid 3D Printing | Fast and cost-effective. Capable of complex geometries that are not possible with other methods. | Material properties might not match those of traditionally manufactured parts. Resolution varies by technology. |

| Rapid Vacuum Casting | Suitable for producing small quantities of highly detailed replicas quickly and affordably. | Generally used for non-functional prototypes or visual models due to material properties. |

Prototyping to Production Support

We focus on providing seamless support for our customers’ innovation journey from prototype production to production. As a comprehensive solution provider, we understand that every step of transforming ideas into market acceptable products is crucial

Rapid Prototypes

Rapid prototypes are swiftly generated to facilitate prompt testing, instant feedback, and continuous refinement, thereby accelerating the pace of development.

Design & Engineering Validation

Prototyping services authenticate design and engineering criteria to ascertain functionality and efficacy prior to large-scale manufacturing, ensuring optimal performance upon mass production.

High Volume Production

The transition from prototype approval to high-volume production is optimized to preserve quality standards while efficiently adhering to production timelines.

Why Choose Us?

At RuiYi, we believe that rapid prototyping is more than just a service – it’s a catalyst for innovation. By empowering our clients with fast, affordable, and high-quality prototypes, we help them turn their ideas into reality faster than ever before. Contact us today to learn more about how our rapid prototyping services can accelerate your product development process and drive your business forward.

Speed & Efficiency

We understand the importance of time in today’s fast-paced business environment. That’s why our rapid prototyping services are designed to deliver high-quality prototypes within 1-3 business days, ensuring your ideas can be tested and refined with lightning speed.

Advanced Technologies

Employing state-of-the-art 3D printing & CNC machining, we fashion precise, long-lasting prototypes faithful to your design concept. Our expertise spans intricate detailing to intricate geometries, turning your vision into reality.

Cost-Effectiveness

By streamlining the prototyping process and leveraging efficient production methods, we offer cost-effective solutions that fit your budget. This allows you to iterate on your designs without breaking the bank, ultimately leading to a more successful product launch.

Expertise & Support

Our team of experienced engineers and designers are dedicated to providing personalized support throughout your entire prototyping journey. From consultation and design optimization to final prototype delivery, we’re here to guide you every step of the way.

Versatility

Whether you need a single prototype for testing or multiple iterations for refinement, we’ve got you covered. Our rapid prototyping services cater to a wide range of industries and applications, from consumer electronics and medical devices to automotive parts and aerospace components.

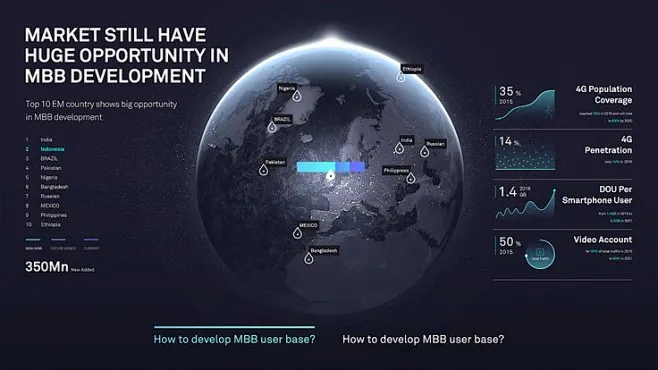

Rapid Prototyping for Various Industries

Ranging from the automotive sector to aerospace, Ruiyi’s CNC machining caters to the exact requirements of various industries. We collaborate with individual inventors, designers, and large corporations, assisting more than 20,000 clients globally.