As an important industrial application material, the surface treatment technology of metal materials has a positive effect on the maintenance of material performance, which can prolong the service life of metal materials. With the continuous development of industrial technology, metal materials are being widely used in various industrial fields. Enhancing their performance, such as corrosion resistance and wear resistance, is currently a hot topic.

Surface treatment technology of metal materials mainly through changing the physical or chemical properties of the metal surface, to enhance the characteristics of the metal, improve the appearance of the metal and environmental performance.

Through the application of surface treatment technology, can make the metal surface gloss higher, improve its hardness and change its chemical properties, and at the same time improve its surface uniformity and flatness, to meet the needs of different industrial fields on the metal surface.

Overview of surface treatment technology for metal materials

Surface treatment of metal materials is through chemical, physical and other ways to form a protective film on the metal surface or by changing the surface oxide layer or the surface molecular structure, thereby enhancing the performance of metal materials, a technical treatment.

Surface treatment technology can be applied in various ways, such as through spraying, plating, shot peening, anodizing, polishing, and so forth.

Through different types of technical treatment, can enhance the performance of metal materials in a certain aspect, such as improving the hardness, corrosion resistance, insulation, optical properties, thermal insulation, electrical conductivity, etc., so as to reduce the maintenance cost of metal materials, extend their service life, and enhance the safety of their industrial applications.

It is evident that the effective surface treatment of metal materials is crucial for achieving the desired effect. As industrial development requirements increase, we must innovate and optimize the technologies for surface treating various types of metal materials to enhance their performance and broaden their industrial applications.

Metal materials surface treatment technology

1. Electrochemical treatment technology

1.1 Anodizing

Anodic oxidation, as a widely used electrochemical treatment technology, effectively forms an oxide film on the metal surface to insulate and protect the entire metal.Additionally, it enhances the decorative appearance of the metal surface.

For example, through anodic oxidation treatment, aluminum and aluminum alloy can achieve double-color, gradient color, and single-color treatment effects, among others. Different processes affect the formation of the oxide film, influenced by factors like the oxidizing agent, current, and temperature.

For example, aluminum and aluminum alloy materials should be treated according to specific requirements in order to achieve a perfect treatment effect.

1.2 Electroplating

Electroplating is a kind of effective treatment to form a layer of metal deposition or metal alloy on the metal surface through chemical electrolysis.

The principle of electroplating is to regard the plated material as the anode and the working pole as the cathode, and make the two enter into the electrolyte together, and the reduction reaction occurs when the current passes through, so that the cathode surface forms a new plated metal layer.

Currently, electroplating technology is more widely used. The plating layer formed through electroplating can alter the material’s resistance and enhance the size, appearance, and electrical conductivity of metal materials.

Specific metal parts in fields like machinery manufacturing, aviation, and electronic engineering primarily utilize electroplating. By forming a protective layer via electroplating, one can effectively improve the service life and performance of various components.

2. Heat treatment technology

Heat treatment is a common surface treatment technology, can change the internal crystals of metal materials through thermal processing, thus changing the surface properties of the metal, improve the resistance of the metal.

Especially in the corrosion resistance, wear resistance and other aspects have significant effects. For example, titanium metal is a class of metal materials that are thermodynamically unstable, and the thermal factors in the environment will have a certain impact on its metal properties.

Titanium metal often undergoes heat treatment technology to enhance its mechanical properties, improving its surface hardness and toughness, and thereby enabling it to adapt to thermal environmental conditions. Heat treatment techniques mainly include quenching and laser surface strengthening.

2.1 Quenching

Quenching technology is a way to change the material properties by heating the material to a certain temperature so that the material reaches a critical temperature and then cools rapidly.

Various mechanical parts undergo quenching treatment technology for strength treatment. Surface quenching not only strengthens the wear resistance and fatigue resistance of the surface of the metal material, but also effectively improves the hardness of the parts.

2.2 Laser surface strengthening technology

Laser surface strengthening technology is an effective method of surface treatment of metal materials using laser, usually through laser treatment to make the metal surface to reach above the melting point of the metamorphic phase, and through rapid cooling to enhance the hardening properties of the metal surface materials.

Laser surface strengthening is only for localized treatment, and is characterized by small impact on the whole metal and convenient operation.

3. Physical treatment technology

Surface modification technology involves coating the surface of metal materials through physical means to enhance their surface properties and, consequently, improve the resistance of the metal materials. This technology primarily encompasses methods such as shot peening, spraying, polishing, and others.

3.1 Shot peening

Shot peening is a kind of cold process through high-speed spray projectile impact on the metal surface, the purpose is to make the material plastic change, so as to enhance the strength of the material surface and fatigue resistance. In addition, shot peening can also effectively eliminate the residual stress on the surface of metal materials produced by welding and other processes.

3.2 Powder Coating

Powder coating is also a widespread physical treatment. One sprays the coating onto the surface of the metal material and bakes it at a high temperature to firmly adsorb the coating onto the metal surface. This method can make the surface of metal materials to form a protective layer, not only can improve the resistance and hardness of the material, but also improve the texture and color of the material.

3.3 Polishing

Polishing is the use of abrasive tools or other technical means to modify the metal surface processing, in order to enhance the smoothness of the metal surface or enhance the mirror gloss.

Manufacturers use polishing in the production of automotive components, stainless steel, and other products to improve the dimensional accuracy and geometric precision of metal materials.

With the current level of technology, one can polish not only through mechanical means but also through electrolysis, chemistry, and other methods.

Advantages of surface treatment technology for metal materials

1. Enhance the corrosion resistance of materials

Metal materials in industrial applications, corrosion is a relatively common problem. Especially in some acidic, alkaline or humid environment, metal materials are susceptible to environmental influences, corrosion, which will not only make the performance of metal materials decline, but also reduce the service life of metal materials.

The surface treatment of metal materials is of great significance to enhance the corrosion resistance of metals. Metal material surface treatment technology, can make the metal surface to form a protective film, effectively isolate the metal layer and the depth of contact with the environment, thus slowing down the oxidation reaction of metal materials, reduce the cost of industrial applications.

2. Enhance the wear resistance of materials

Many metal materials used in industrial applications are often in a state of friction. If their surfaces are not technically treated, they can easily undergo material wear, thereby reducing their useful life.

Environmental conditions, such as high-speed operation and exposure to high temperatures and high humidity, further diminish the surface wear resistance of metal materials. Therefore, the surface treatment of metal materials is particularly necessary. You can choose laser strengthening or spraying and other treatment techniques to improve the surface hardness of the metal material, so as to improve its degree of wear resistance.

Simultaneously, one can alter the particle structure of the metal surface to enhance its wear-resistant strength, thereby improving the wear resistance of metal materials and extending their service life.

3. Improve the aesthetics of the material

Metal material surface treatment technology can also change the color, texture, and gloss of the metal surface, enhance the visual aesthetics of the metal, and improve the decorative properties of the material.

For example, the automobile manufacturing industry tends to effectively decorate the metal surface through polishing, electroplating, spraying and other treatment technologies, or through individual needs to deploy various types of parameters to enhance the beautification effect of automobile decoration, and at the same time to enhance the durability of the metal to maintain a variety of use functions.

4. Meet other special requirements of materials

With the rapid development of the times, the needs of the industrial field are becoming more and more diversified, metal materials must meet more special requirements and functions.

For example, in the spraying process to add lubricants to enhance the lubrication function of the metal surface; add conductive coatings to make the metal to produce conductive function; the use of chemical coating to make the metal surface to form a micro-nanostructure, enhance the metal antimicrobial function.

Diversified means of treatment not only to meet the individual needs, but also to expand the industrial applications of metal materials, and thus promote the innovation and upgrading of technology.

The application of metal material surface treatment technology in industry

The industrial application of metal material surface treatment technology is more extensive, not only widely used in the automobile manufacturing industry, electronics manufacturing industry, but also in the aerospace field, machinery manufacturing and other industries have applications.

1. Application in automobile manufacturing industry

In the automobile manufacturing industry, the surface treatment of metal materials is particularly important, but also a common technical means. Simultaneously, one can alter the particle structure of the metal surface to enhance its wear-resistant strength, thereby improving the wear resistance of metal materials and extending their service life.

Therefore, the metal material will be according to the role of different parts of the targeted surface treatment.

For instance, extended exposure to the external environment makes automobile chassis, bodies, and other parts more susceptible to environmental impacts, particularly high temperatures and high humidity, which can cause corrosion and oxidation of the parts, thereby impacting their performance. To combat this, manufacturers can apply surface treatments such as spraying or plating to the metal materials to form a protective film on the surface, thus enhancing the corrosion resistance of the parts.

Another example, the automobile transmission shaft, engine bearing parts and other long-term in the rotating friction state, for wear resistance requirements are high.

In the surface treatment technology, laser technology and wear-resistant coating spraying and other technologies to enhance the wear resistance of parts, thereby extending the service life of parts. In addition, the appearance of automobile spraying is also particularly necessary, through the enhancement of the color and texture of different coatings, can make the car appearance more beautiful.

Therefore, for the automobile manufacturing industry, metal material surface treatment technology for different parts to take differentiated treatment means, can help enhance the market competitiveness of automotive products.

2. Application in automobile manufacturing industry

Electronic manufacturing industry in the metal material surface treatment technology is equally important. Electronic parts and components are required to have insulation, corrosion, heat dissipation, conductivity and other properties.

In the insulation and anti-corrosion, electronic products through spraying, plating and other surface treatment technology to make the surface of metal materials to form a protective film, improve the stability of the material in the use of the process, and at the same time effectively improve the insulation of metal materials, so that it is still able to maintain stable performance in different environments.

Some parts of electronic products will be connected to the circuit board or play the role of the connector, which needs to have good electrical conductivity.

For example, in the metal surface treatment, through electroplating technology to add conductive materials can form a good conductive layer to enhance the conductivity of the product.

In addition, in order to maintain good heat dissipation, the surface treatment of metal materials will often use thermal spray technology to increase the heat dissipation coating, optimize the heat dissipation performance of metal materials, and further enhance the stability of product operation.

3. Application in automobile manufacturing industry

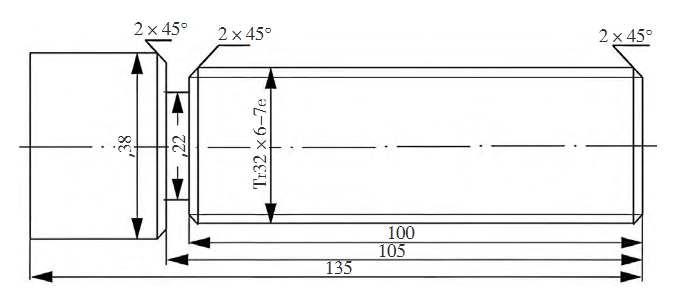

The machinery manufacturing industry has relatively high requirements for metal materials, not only in the hardness enhancement, but also focuses on the repair of the size and dimensions of the parts.

Therefore, in the surface treatment technology, will be based on different requirements for targeted treatment.

For example, to enhance the wear resistance of mechanical parts, manufacturers will use methods such as laser reinforcement spraying to apply wear-resistant layers and other techniques to improve the metal’s wear resistance. Similarly, to address corrosion resistance and other changes in surface properties, they will employ technologies like chemical oxidation and shot peening to alter the physical or chemical properties of the metal surface, thereby enhancing the parts’ resistance.

In addition, some parts in the wear process will appear deformation, wear too fast, etc., for such parts can be achieved through thermal spraying and other technologies to repair the size, size, in order to enhance the stability of its performance, and to realize the recycling of parts.

4. Application in aerospace field

In the aerospace field, the surface treatment technology of metal materials is particularly important. Especially for some key parts in the aerospace industry, in the harsh high-temperature environment, the requirements for anti-oxidation, high temperature resistance, corrosion resistance and so on are relatively high.

Therefore, surface treatment of such materials is required.

For example, the turbine blades of aviation engine components are usually operated under high temperature environment, it is necessary to implement high temperature resistant coating technology for such blade parts to make them maintain stable performance in high temperature conditions, while for the parts that are susceptible to oxidation or corrosion, spraying, plating and other technologies are used to deal with the surface of the formation of stable protective coatings, so as to reduce the corrosion or oxidization of the parts.

In addition, for aerospace parts in the weight of the strict requirements, will be part of the metal materials for lightweight processing to ensure that it should be in the abrasion resistance, corrosion resistance and other strength requirements, but also reduce the overall weight to meet the use of aerospace aircraft needs.

5. Application in light industry

Metal surface treatment technology also plays a pivotal role in light industry. With the continuous improvement of people’s demand for product appearance and functionality, the application of metal surface treatment technology to the field of light industry has become more and more extensive, which significantly improves the overall market competitiveness of light industrial products.

Through anodic oxidation, electroplating and other forms of technology to enhance the light industry products of various types of abrasion resistance, corrosion resistance, but also the appearance of the product aesthetics in-depth thinking, enhance the attractiveness of the product, enhance the overall sales value.

For example, the furniture manufacturing field through the use of metal materials surface treatment technology to enhance the novelty of furniture manufacturing and appearance of wear resistance; metal packaging used in the food industry, through the surface treatment technology to enhance the aesthetics of the packaging, improve its corrosion resistance, wear resistance and other properties.

In addition, with the growing awareness of environmental protection in various fields, metal surface treatment technology is moving towards a more environmentally friendly, green direction, while also thinking about how to reduce energy consumption, environmental pollution.

It can be seen that the surface treatment technology of metal materials for the development of light industry provides more possibilities, and its technological breakthroughs and quality enhancement, to meet the needs of modern groups of environmental protection, aesthetics, durability and other aspects of the product, and to promote the development of light industry at a high level.

Conclusion

The industrial application of surface treatment technology of metal materials is relatively wide, is an effective way to change the performance of metal materials, can enhance the hardness of metal materials, reduce the corrosive nature of the material, improve its wear resistance, thereby extending the service life of the material, while meeting the requirements of the development of different industrial fields, as well as the group for the diversified needs of metal materials.

With the intelligent development of the industrial field, metal material processing technology is moving towards automation, multi-functionality, environmental protection and other directions, which not only expands the application field of metal materials, but also promotes the innovative development of industrial technology.