The importance of three-coordinate measurement in mechanical manufacturing

In mechanical manufacturing, three-coordinate measurement plays a vital role as a high-precision technical means, widely used in product design, processing and manufacturing, and quality control. Through the precise measurement of the spatial coordinates of the object’s surface, three-coordinate measurement provides the necessary geometric information for the manufacturing process, which helps improve manufacturing accuracy, ensure product quality, and improve production efficiency. The following will detail the core importance of three-coordinate measurements in mechanical manufacturing.

1. The key role of the product design stage

In mechanical manufacturing, product design is the starting point of the manufacturing process, and the accuracy of the design directly affects the final quality and performance of the product. Three-coordinate measurement provides key data support in the design stage. By accurately measuring the size, shape, and other parameters of the parts, designers can ensure that the design meets the expected requirements. This can not only reduce the need for later adjustments and modifications but also improve design efficiency and ensure the manufacturability and reliability of the product. Accurate design lays a solid foundation for subsequent processing and assembly and avoids production problems caused by design errors.

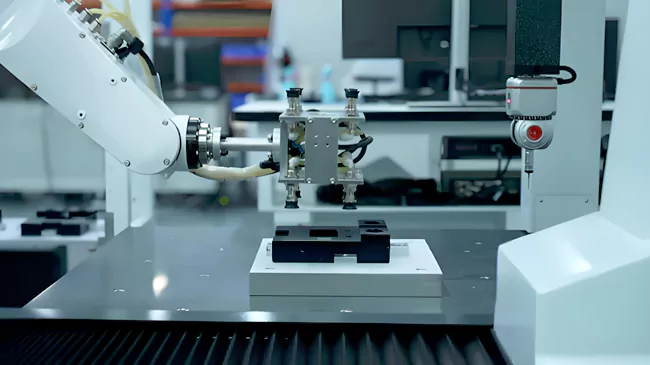

2. Irreplaceability in processing and manufacturing

In modern machinery manufacturing, high-precision processing of parts is the basis for ensuring product performance and quality. Three-coordinate measurement technology can monitor and control key dimensions and shapes in real time to ensure that the accuracy of parts processing is consistent with design requirements. This is particularly important for the production of precision mechanical parts, especially in high-tech fields such as aerospace and automobile manufacturing. Three-coordinate measurement plays a key role in ensuring the processing quality of parts and the performance of the final product.

3. Application in quality control

Product quality is the embodiment of the competitiveness of manufacturing companies and the main basis for consumers to choose products. Three-coordinate measurement provides accurate testing tools for quality control. By comprehensively testing the produced parts, companies can ensure that each part meets the design specifications and quality standards. This not only helps to improve the product qualification rate but also can promptly detect and eliminate potential manufacturing defects and reduce the defective rate. Further, the application of three-coordinate measurements helps companies save production costs and enhance market competitiveness.

4. Comprehensive monitoring and optimization of the manufacturing process

In addition to its application in product design, processing, and quality control, three-coordinate measurement also plays a role in optimization and intelligent manufacturing in the manufacturing process. By collecting and analyzing three-coordinate measurement data in real time, manufacturing companies can fully understand the situation of the production process, adjust production parameters in time, and optimize the process flow. This not only improves production efficiency, but also reduces resource waste, reduces production costs, and provides support for enterprises to achieve sustainable development.

Principles and characteristics of three-coordinate measurement technology

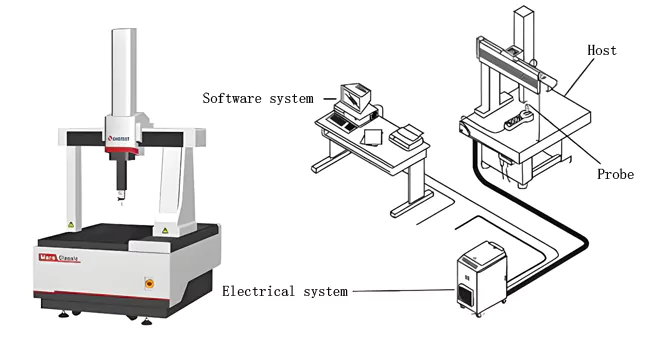

Coordinate measurement technology plays a vital role in the field of mechanical manufacturing. It ensures product quality and improves production efficiency by accurately measuring the three-dimensional coordinates of objects. This technology involves the collaborative work of measuring mechanisms, probes, and software. Its principles and characteristics provide a strong guarantee for precision measurement and quality control in mechanical manufacturing.

1. Principles of three-coordinate measurement technology

Three-coordinate measurement technology is based on a three-dimensional coordinate system. By accurately measuring the surface of an object, we can obtain key feature information such as size and shape. We can divide its core principles into the following parts:

Measuring mechanism: The measuring mechanism of a three-coordinate measuring machine usually includes three mutually perpendicular axes, namely X, Y, and Z axes. These three axes control the movement of the probe in different directions to ensure that the position of the object can be accurately located and measured. Through the movement of these three axes, the measuring mechanism can fully scan the measured object and capture its three-dimensional spatial coordinates.

Measuring probe: The measuring probe is a key component to achieving actual measurement. It obtains data on the surface of the measured object by contact or non-contact means. Contact probes measure surface features by physical contact, while non-contact probes measure by laser, optical, or other technologies. The high precision of the probe enables three-dimensional coordinate measurement to obtain accurate three-dimensional coordinates.

Measurement software: The measurement software processes and analyzes the data collected by the probe in real time. It calculates the three-dimensional coordinates of the object, generates a measurement report, and can perform data analysis on the measurement results to help detect the qualification and accuracy of the product and provide comprehensive quality control data.

2. Characteristics of three-coordinate measurement technology

Three-coordinate measurement technology has many unique characteristics in mechanical manufacturing, which makes it an ideal choice for precision manufacturing and quality control.

High-precision measurement: Three-coordinate measurement can accurately locate and measure objects in three-dimensional space. Compared with traditional two-dimensional measurements, it can provide more detailed information and ensure high-precision measurement results. This is crucial for demanding manufacturing tasks, especially in industries such as aerospace, automotive, and electronics.

All-round measurement capability: Unlike traditional measurement methods, the three-coordinate measurement system uses a three-dimensional coordinate system, which can capture the spatial shape of an object in all directions. It can accurately measure complex shapes, curved surfaces, holes, uneven surfaces, etc., so it is suitable for measuring parts with complex shapes.

Flexibility and strong adaptability: The three-axis movement of the measuring mechanism makes the three-coordinate measurement system highly flexible, able to measure objects of various shapes and adapt to different types of parts, especially for parts with complex structures such as porous structures and thin-walled parts.

High efficiency and high reliability: Three-coordinate measurement can not only provide high-precision measurement results, but also reduce human errors during the measurement process, and improve the efficiency and reliability of measurement. For mass production, three-coordinate measurements can improve the level of production automation and provide accurate data support for quality control.

3. Limitations of three-coordinate measurement technology

Influence on flexible materials: The contact measurement probe may deform flexible or deformable objects when it contacts the surface of the object being measured, which affects the accuracy of the measurement results. Therefore, non-contact measurement technology may be more suitable in some cases.

Equipment size limitation: To measure large objects, manufacturers need larger coordinate measuring machines, which not only increase equipment costs but also require more space to accommodate these devices . Therefore, for larger workpieces, it may be necessary to customize higher-specification measuring equipment.

Longer measurement time: Compared to other measurement technologies, three-coordinate measurement takes longer to perform, especially when measuring complex workpieces with high precision, which can increase the production cycle e.Therefore, for batch measurement tasks on the production line, the three-coordinate measurement may not be suitable for occasions with high-efficiency requirements.

4. Comparison of three-coordinate measurement technology with other measurement technologies

Compared with optical measurement technology: Optical measurement technology is usually limited by surface finish and reflection characteristics, while three-coordinate measurement technology performs all-around accurate measurements on complex surfaces and under occlusion conditions. Especially for complex geometric shapes, three-coordinate measurements can provide more detailed spatial coordinates.

Compared with laser scanning technology: Laser scanning technology is suitable for large-scale 3D modeling and surface scanning, but its measurement accuracy is not as good as three-coordinate measurements. For applications that require high-precision dimensional control, three-coordinate measurement technology can provide more accurate measurement results, especially in areas with high dimensional accuracy requirements.

Compared with two-dimensional measurement technology: two-dimensional measurement technology can only measure the plane size of an object and lacks a comprehensive understanding of the shape and position of the object. Three-coordinate measurements can capture the three-dimensional information of an object, provide more complete and accurate measurement data, and significantly improve the accuracy and reliability of measurement.

Practical strategies for the application of three-coordinate measurement in the field of mechanical manufacturing

1. Parts inspection and quality control

In the field of mechanical manufacturing, three-coordinate measurement technology (CMM) as a high-precision measurement method plays a vital role in parts inspection and quality control. By accurately measuring the size, shape, and position of parts, three-coordinate measurement technology can effectively ensure product quality, improve production efficiency, and reduce scrap rate. It is an indispensable key technology in the modern manufacturing process.

(1) Accurate measurement of part size

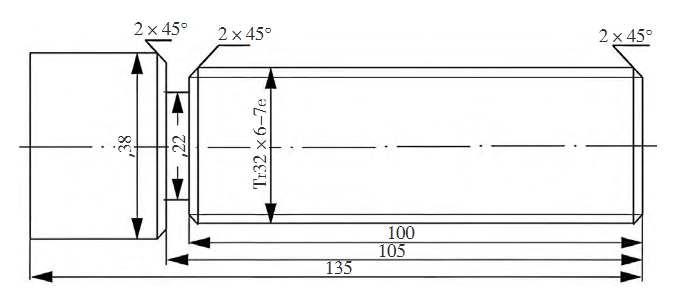

In mechanical manufacturing, especially for key parts such as high-precision machine tools, the size requirements are extremely strict. The deviation can usually be controlled within a few microns, but traditional measurement methods struggle to meet this high standard. The three-coordinate measuring machine can quickly and accurately measure the various dimensions of parts through its high-precision probe. By establishing a three-dimensional coordinate system, the three-coordinate measuring machine can capture the dimensional information of parts in all directions to ensure that it is completely consistent with the accuracy requirements in the design drawings.

Take the key parts of a high-precision machine tool as an example. The dimensional requirements of these parts are very fine. The three-coordinate measurement technology can ensure the accuracy of the parts through precise measurement, avoiding poor assembly or product performance degradation caused by dimensional errors.

(2) Accurate measurement of part shape

For parts with complex shapes, traditional measurement methods may find it difficult to cover all surface features. The three-coordinate measurement technology can accurately measure complex geometric shapes such as curved surfaces and holes through highly flexible probes. This makes three-coordinate measurements particularly important in aerospace, automobile manufacturing, and other fields.

For example, in the production of aircraft engine blades, the blade surface is usually full of complex curves and irregular features, and it is necessary to ensure that its shape meets aerodynamic requirements. The three-coordinate measuring machine can complete the shape scan of the entire blade surface in a short time and generate accurate three-dimensional data, providing reliable data support for subsequent assembly and use. This high-precision shape measurement technology can effectively ensure the functionality and performance of complex parts and avoid shape errors affecting product quality.

(3) Precise control of parts position

In some assembly processes that require a high degree of coordination, the relative position accuracy of parts is crucial to product quality. Three-coordinate measurement technology can accurately measure and locate the position of parts, ensure that the coordination between parts during assembly meets the design requirements, and reduce assembly errors.

For example, at the connection between the cylinder block and the cylinder head of an automobile engine, the precise coordination of the position requires extremely high sealing. Through three-coordinate measurement technology, we can ensure the accurate and correct relative position between the cylinder block and the cylinder head, preventing poor sealing caused by position deviation, which in turn affects engine performance and vehicle reliability.

(4) Improving production efficiency and reducing scrap rate

Three-coordinate measurement technology not only plays a key role in the manufacturing stage of parts but also effectively improves efficiency and reduces scrap rates throughout the entire production process. By introducing three-coordinate measurement technology at key production nodes, manufacturers can monitor the production process ireal timeme, promptly discover deviations in the size, shape, or position of parts, and quickly adjust production equipment.

On an automobile production line, we can place a three-coordinate measurement device at key assembly nodes to monitor the quality of parts in real time, detect and correct size or position deviations, and prevent scrap from being generated. This not only improves production efficiency but also reduces production costs. Real-time quality control and adjustment make the production process more precise and efficient, greatly enhancing the company’s competitiveness in the market.

2. Mold design and manufacturing assistance

In the mold design and manufacturing process, three-coordinate measurement technology (CMM) as a high-precision measurement tool plays a vital role in ensuring mold quality, improving production efficiency, and avoiding later problems. Through precise geometric shape, size, and position detection, three-coordinate measurement technology helps designers and manufacturers monitor and optimize mold accuracy in real-time at various stages to ensure design accuracy and efficiency in the manufacturing process.

(1) Auxiliary role in the mold design stage

In the mold design stage, three-coordinate measurement technology provides designers with the necessary support by accurately obtaining key information such as the size, shape, and position of parts. Especially for the design of complex molds, three-coordinate measurements can detect the geometric features of parts in an all-round and multi-dimensional manner, ensure the consistency of parts with design drawings, and promptly discover potential design defects.

For example, in the design process of injection molds, designers need to strictly verify the size and shape of the mold cavity and the matching relationship between the various parts. Through three-coordinate measurements, designers can accurately measure the size of each component in the mold and compare them with the design requirements. If the designer finds any deviation, such as an error in the mold cavity size, they can make timely corrections before production, thus avoiding water quality problems caused by factors such as material shrinkage.

In addition, three-coordinate measurements can also verify the fit relationship between different parts. In a mold composed of multiple parts, the geometric fit accuracy between parts directly affects the assembly of the mold and the quality of the final product. Through three-coordinate measurements, designers can ensure that the fit relationship between the various parts meets the design requirements and avoid assembly problems or quality defects caused by poor fit.

(2) Real-time monitoring and adjustment during mold manufacturing

The mold manufacturing process involves multiple complex processes, such as milling, cutting, grinding, and assembly. The accuracy of each link is crucial to the quality of the final mold. Introducing three-coordinate measurement technology in these processes can monitor the geometric features of the parts in real-time, detect errors in the manufacturing process promptly, and make adjustments to ensure the accuracy and stability of the mold.

Using three-coordinate measurement technology, we accurately detect the key surfaces after completing the milling process. If errors occur during the milling process, the three-coordinate measurement system can immediately detect and generate feedback. Manufacturing personnel adjust the tool position or correct the tool compensation based on the measurement data to ensure that they carry out each process within the allowable error range. This real-time detection and feedback mechanism not only ensures the accuracy of parts but also prevents quality problems caused by the accumulation of unqualified processes.

In the subsequent grinding and assembly process, three-coordinate measurement technology also plays an important auxiliary role. By monitoring the surface of the polished parts in real-time, we can avoid the problem of dimensional non-conformance caused by excessive grinding. Especially for parts of the mold that require high precision, such as the matching surface of the mold, three-coordinate measurements can ensure that the size of the polished parts is consistent with the design requirements and avoid human errors. During the assembly stage, we detect the relative position of each component using three-coordinate measurement technology to ensure the matching accuracy between components. This improves the accuracy and efficiency of mold assembly and ensures the quality of the final product.

(3) Optimize production processes and improve manufacturing efficiency

By introducing three-coordinate measurement technology, the mold manufacturing process can not only improve the quality of a single component but also optimize the entire production process. Real-time measurement and feedback can not only detect and correct errors in time, but also reduce production cycles and improve production efficiency. Especially in mass production, three-coordinate measurement can help quickly locate and solve problems, and avoid the production of a large number of defective products, thereby reducing production costs and improving overall production efficiency.

For example, in the mass production process of molds, by introducing three-coordinate measurement equipment at key nodes of the production line, manufacturing personnel can monitor the quality of parts in real time, adjust production equipment and process parameters in time, and ensure that all indicators in the entire production process are within the qualified range. By reducing the scrap rate and improving the controllability of production, enterprises can increase production speed while ensuring quality.

3. Complex parts and surface measurement

In the field of mechanical manufacturing, three-coordinate measurement technology plays a vital role in the precise measurement of complex parts and surfaces. With the increasing sophistication of manufacturing processes, especially in industries with high precision requirements such as aerospace, automobiles, and molds, three-coordinate measurement technology has become an important tool to ensure product quality, improve manufacturing accuracy, and ensure industrial production efficiency. The following will discuss in detail the application of three-coordinate measurement technology in the measurement of complex parts and surfaces and its unique advantages.

(1) Complex Part Measurement

The measurement of complex parts is crucial to the accuracy of product assembly, especially in high-precision products involving multiple parts, such as aerospace and automotive engine parts. Take aircraft engine parts as an example. These parts often have complex surfaces and precise structures. Traditional measurement methods cannot meet the high-precision requirements. However, three-dimensional coordinate measurement technology, with its high-precision measurement probe, can accurately capture the three-dimensional coordinate information of the surface of the parts.

By establishing a mathematical model, three-dimensional measurement can comprehensively analyze the geometric characteristics of the parts, including curvature, surface deviation, position tolerance, etc. This process provides real-time feedback for manufacturing process optimization and ensures the precise matching of parts during assembly. For example, in engine assembly, if there are slight dimensional deviations between parts, it may affect the overall performance. Through three-dimensional coordinate measurement technology, manufacturing personnel can detect these deviations in time and make adjustments, thereby improving assembly quality and ensuring the function and stability of the entire product.

(2) Surface measurement

Surface measurement plays a vital role in many industries, especially in mold and automobile manufacturing. Taking automobile shell manufacturing as an example, the accuracy of the external surface directly affects the appearance quality of the vehicle and its aerodynamic performance. Three-coordinate measurement technology can accurately measure the curvature and shape information of the mold surface, providing strong support for mold design and mold repair process.

In mold manufacturing, especially in the production of injection molds or die-casting molds, three-coordinate measurements can not only check the flatness and geometry of the mold surface but also monitor the changes of the mold in real-time. Through accurate measurement of the mold, the manufacturer can adjust the production parameters in time to ensure the accuracy and stability of the mold. This real-time monitoring process ensures the dimensional accuracy of the mold and avoids later problems caused by dimensional errors, thereby improving the manufacturing accuracy of the mold and the quality of the final product.

(3) Surface measurement in aerospace device manufacturing

The measurement of complex parts is particularly critical in aerospace device manufacturing. Take the turbine blades of spacecraft as an example. Turbine blades usually have complex curved surface structures and require extremely high processing accuracy. The surface morphology of turbine blades is closely related to aerodynamic performance, so accurate surface measurement is crucial to ensure their performance and reliability.

Through three-coordinate measurement technology, we can accurately measure key parameters such as curvature, angle, and geometric features of turbine blades. With the help of these measurement data, manufacturers can build a three-dimensional model and gain a deep understanding of the geometric characteristics of the blades. During the manufacturing process, real-time measurement and feedback enable manufacturing personnel to adjust processing parameters promptly to ensure that the accuracy of the turbine blades is consistent with the design requirements, thereby improving the aerodynamic performance of the blades and the overall efficiency of the engine. For high-demand aerospace parts, three-coordinate measurement technology ensures the processing accuracy of the parts, thereby ensuring the efficient operation and reliability of the engine.

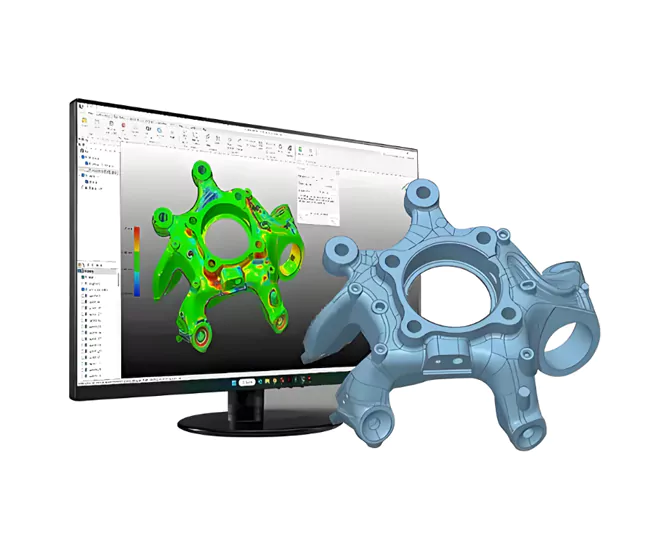

4. Reverse engineering and replica manufacturing

Reverse engineering and replica manufacturing are important application strategies of three-coordinate measurement technology in the field of mechanical manufacturing, and play a key role in innovative design and improving production efficiency. By digitizing and reproducing physical objects, reverse engineering and replica manufacturing not only provide technical support for the precise remanufacturing of complex parts and products but also provide a powerful tool for innovation in the manufacturing process.

(1) Reverse engineering

Reverse engineering is a process of generating a digital model of an existing object by performing three-dimensional scanning and data collection, and then designing, analyzing, or remanufacturing based on the model. Three-coordinate measurement technology plays a key role in reverse engineering, which can accurately obtain the geometric information of the object and provide reliable data support for subsequent design and optimization.

For example, in automobile manufacturing, reverse engineering technology can quickly obtain the geometric parameters and structural features of automobile parts by scanning and measuring them. This provides accurate basic data for subsequent product optimization, design modification, or production of replacement parts. Reverse engineering not only helps design new products but also provides solutions for replacing old parts, extending equipment service life, and reducing costs.

(2) Replica manufacturing

Replica manufacturing is an extension of reverse engineering. It refers to the process of accurately obtaining the geometric information of existing products and remanufacturing the same or similar products on this basis. Replica manufacturing is particularly important in large-scale production and parts replacement. It can ensure that the manufactured parts are the same as the originals, and even reach the same level of performance.

Taking aircraft engine blades as an example, three-coordinate measurement technology can accurately obtain key parameters such as the curvature, angle, and surface quality of the blades. These data allow us to replicate the blades, ensuring that the geometric features and performance of the replicas match the originals, thereby improving the performance and reliability of the aircraft. Replica manufacturing is not only suitable for the remanufacturing of high-precision parts but also for mass production of parts, improving production efficiency by reducing production costs and cycles.

(3) Advantages of reverse engineering and replica manufacturing

Time and cost savings: Reverse engineering can quickly obtain geometric information of existing products, reduce the time for design and trial and error, and significantly shorten the product launch cycle. Compared with traditional design and manufacturing from scratch, reverse engineering can quickly respond to market demand and enhance the market competitiveness of enterprises. Replica manufacturing avoids the process of repeated design by remanufacturing existing products, which greatly saves time and cost.

Adapt to complex or difficult-to-design parts: Reverse engineering technology performs particularly well when facing complex shapes and parts that are difficult to handle with traditional design methods. For some old equipment that cannot directly obtain design data or parts that are difficult to manufacture by traditional means, reverse engineering can provide accurate digital models through scanning and measurement, to carry out subsequent design and remanufacturing.

Personalized customization: Reverse engineering and replica manufacturing enable personalized customization, particularly in the fields of medical devices and artwork reproduction. For example, the medical industry uses reverse engineering technology to scan specific organs of patients to manufacture personalized medical devices that meet the needs of patients.

(4) Challenges and limitations of reverse engineering and replica manufacturing

Limitations of capturing subtle features: For some complex or tiny structures, three-coordinate measurement technology may not be able to fully capture their subtle geometric features. This may lead to incomplete or inaccurate digital models, which in turn affects the accuracy of subsequent manufacturing processes.

Technical threshold: Reverse engineering not only requires high-precision measurement equipment but also requires professionals to perform data processing, model reconstruction, and subsequent design. This may face high technical barriers and costs for some small and medium-sized enterprises.

Intellectual property issues: Reverse engineering and replica manufacturing face intellectual property and legal risks. Unauthorized copying may infringe on the patent or copyright of the original product, leading to legal disputes. When applying reverse engineering and replica manufacturing, companies need to pay attention to intellectual property protection to avoid infringing on the innovative achievements of others.

(5) Practical applications of reverse engineering and replica manufacturing

Medical devices: In the medical field, companies widely use reverse engineering technology to manufacture personalized medical devices. For example, by three-dimensional scanning of a patient’s specific organs, they can create personalized prostheses or implants to provide tailored treatment plans for patients.

Aerospace: In the aerospace field, engineers can use reverse engineering technology to remanufacture old parts or produce replacement parts. By accurately obtaining the geometric information of the parts, they can produce parts that are consistent with the originals, thereby ensuring the safety and reliability of the aircraft.

Artwork reproduction: Artists widely use reverse engineering technology in the field of artwork reproduction. By performing three-dimensional scanning on precious artworks or historical relics, we can reproduce replicas that are consistent with the originals with high precision. This not only helps protect the originals but also allows more people to appreciate these precious works of art.

Conclusion

As an important tool in the field of modern mechanical manufacturing, three-coordinate measurement technology provides key support for achieving high-precision and high-quality manufacturing. By deeply understanding its principles, advantages, and limitations, we can better utilize this technology to achieve better results in parts inspection, mold design, complex parts measurement, and reverse engineering. In the future, with the continuous development of technology, three-coordinate measurement technology will continue to play an important role in mechanical manufacturing and drive the industry forward.