Accelerating the path of customization

Achieving simpler and faster on-demand manufacturing of high-quality parts

Our Manufacturing Services

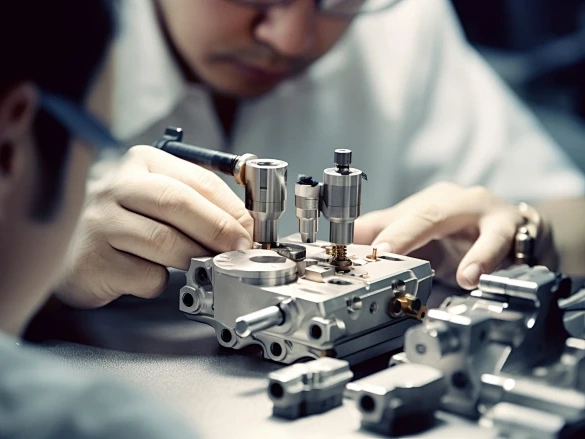

Transitioning seamlessly from rapid prototyping to full-scale production, we specialize in crafting products with intricate designs and stringent aesthetic requirements. Leveraging the expertise of our skilled professionals and cutting-edge technologies, we offer a diverse array of tailored manufacturing solutions to meet any demand.

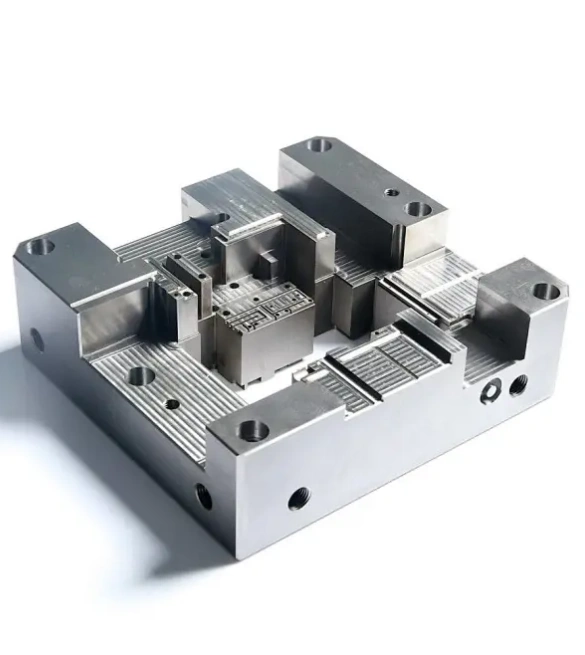

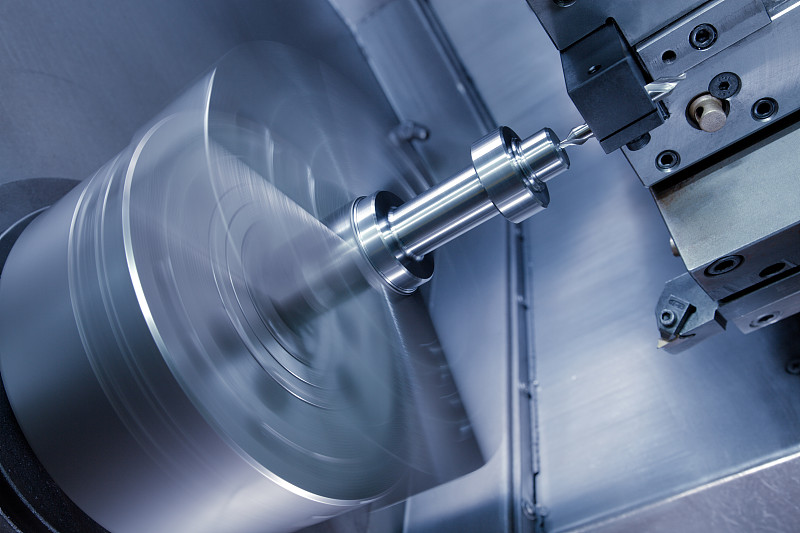

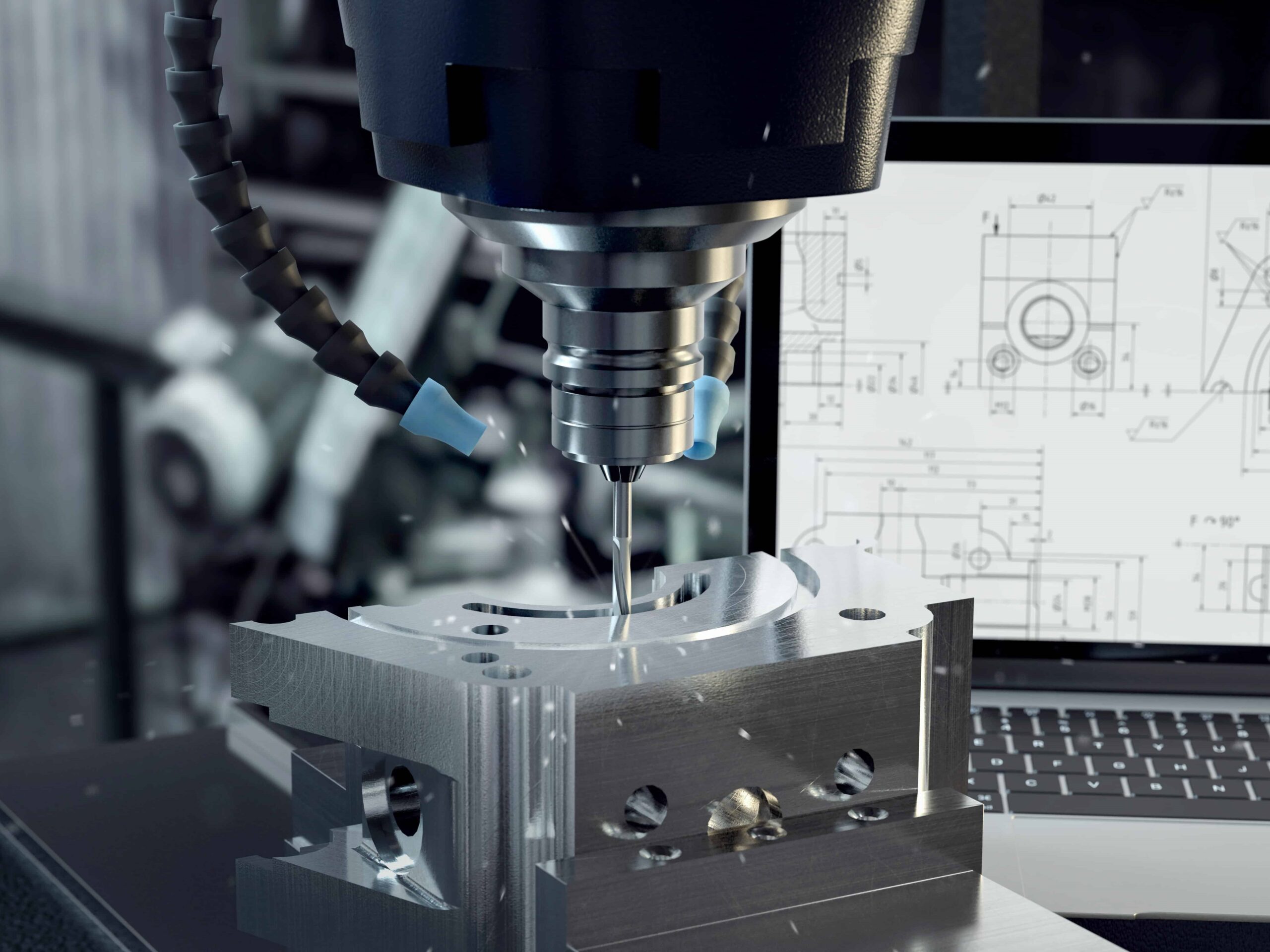

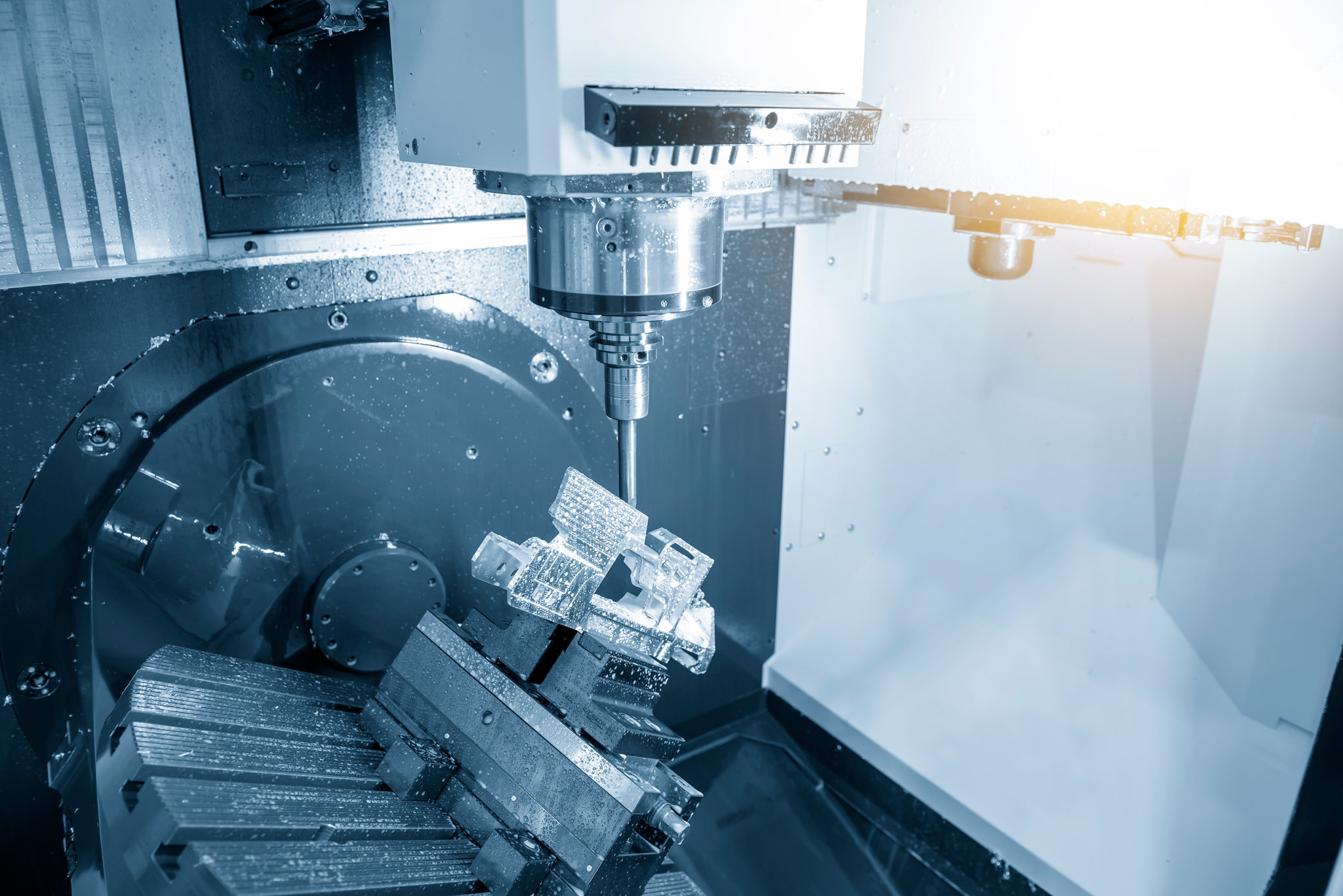

CNC Machining

Craft intricate, precise designs utilizing milling, turning, and subsequent processing techniques, perfectly suited for both intricate prototypes and functional metallic components.

Rapid Prototyping

Efficiently generating a small batch of parts at low expenses is facilitated by rapid prototyping, which embraces various technologies such as diverse 3D printing approaches and urethane casting methods.

Sheet Metal Fabrication

Offers versatility in crafting precise metal parts specifically designed for diverse applications, guaranteeing adaptability and accuracy.

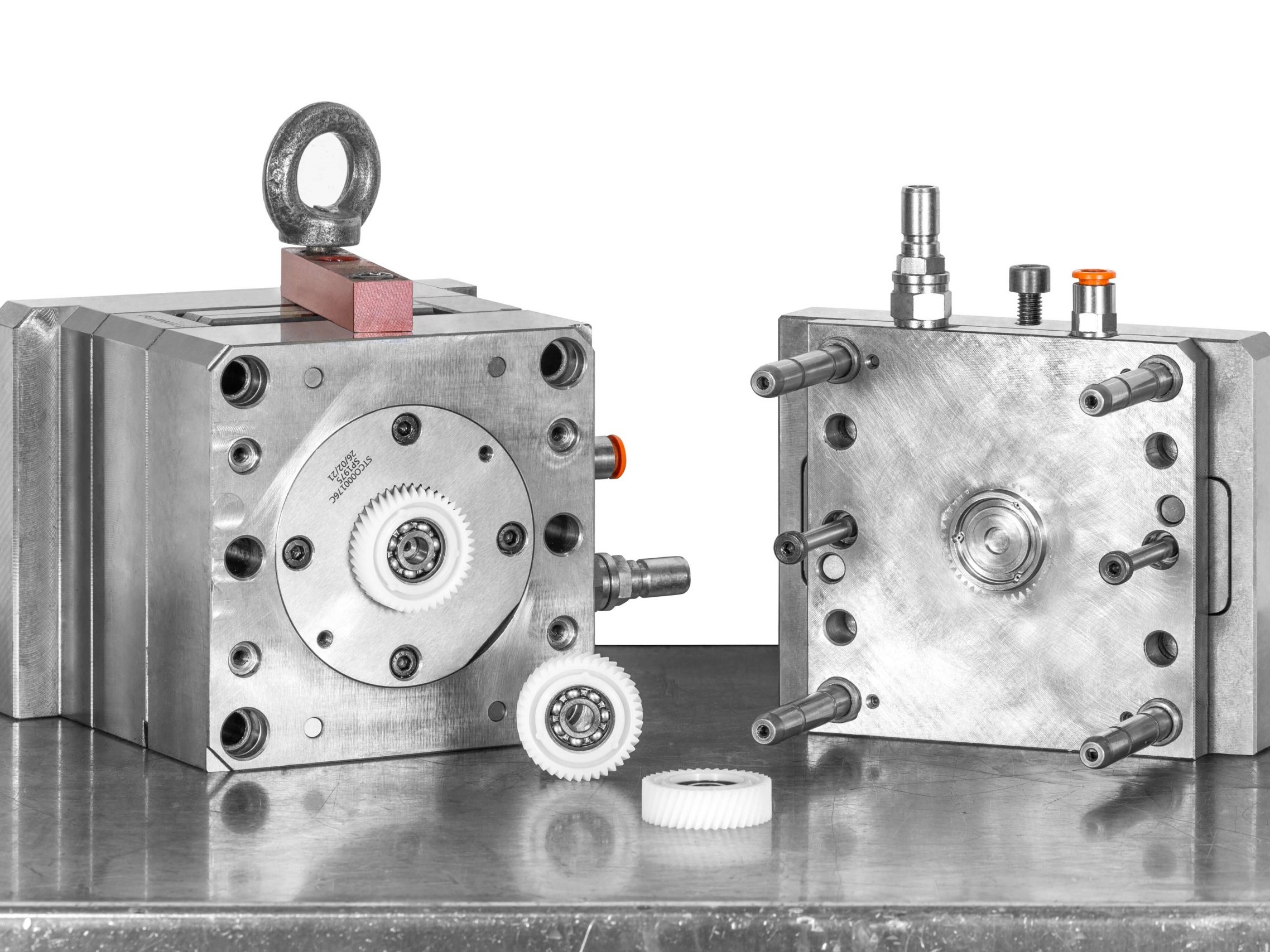

Injection Tooling

We excel in rapid and production mold making. Rapid molds are best for 1000-30,000 plastic parts. Production molds serve large-scale projects over 30,000 parts.

Injection Molding

Quickly manufacture molded components and create tooling bridges, tailored for large-scale production with guaranteed uniformity in quality.

Die-casting High-pressure

The prevalent process for mass-producing metal parts involves primarily Aluminum Alloy, Zinc Alloy, and Magnesium Alloy as the most commonly utilized materials.

Some Number About Us

Annually Turnover

Customers Server Annual

Manufacturing Facilities

Convenient for Youself

One stop prototyping to product solutions

We facilitate your transformation from an initial concept to a finalized product through our all-inclusive prototyping and production services.

Rapid Prototyping

We materialize your concepts into precise, tangible prototypes, expediting product evolution through advanced technologies such as 3D printing, CNC manufacturing, and injection molding. Our methodology fosters swift evaluation and verification of components, streamlining the transition from idea to market readiness.

Low and High-Volume Production

RapidDirect’s digital manufacturing ecosystem robustly facilitates seamless high-volume production, backed by a groundbreaking quotation system, an extensive partner network, and cutting-edge facilities. This guarantees uniform quality standards and cost-effective pricing tailored to all customized production requirements.

Why Choose Us?

Dedicated to personalized support, we strive for excellence, distinction, & partnership in product development.

Upload design to get quick quotes & free design review for prototypes & parts.

Get Instant Quote

Place your order, we start production, and our platform keeps you updated in real-time.

Start Production

A manufacturability assessment of your design will be finalized in a matter of hours.

Perform Design Analysis

Parts pass QC, then packed securely for shipping. 30-day quality guarantee included.

Receive Your Parts

JE Machining

How Can You Collaborate with Us?

To commence, pick a service, then upload a .stp file. Shortly thereafter, we’ll provide you with an Engineering analysis (DFM) and pricing. Once you’ve given your approval, we’ll initiate the manufacturing process. Your parts will be crafted and delivered to you within a few days.

More Professional Services

Collaborative client strategies

Strategic client partnerships drive joint project success. We actively listen to comprehend & fulfill your needs.

Continuous client communication is vital. Together, we overcome obstacles to accelerate goal achievement.

Mold design optimization

We specialize in mold design optimization, leveraging decades of expertise to enhance efficiency & productivity. Our skilled engineers ensure cost-effective solutions. Advanced tech aids in preemptive issue resolution, minimizing expenses throughout the project.

One-Stop Services

Our focus: maximizing your investment. Aria’s streamlined cost planning covers design, production, molding, assembly, & logistics. Tailored optimization for maximum ROI. Contact us now for a quick injection molding quote!

Industries JE Machining

JE Machining provides exceptional global production services tailored to immediate demands. Our primary strength lies in our burgeoning customer portfolio, which has expanded swiftly through positive referrals globally. This diverse clientele spans from individual inventors and designers to prestigious corporations operating in various sectors such as industry, commerce, healthcare, automotive, and even aerospace.